In today’s fast-paced manufacturing environment, agility, accuracy, and collaboration are more essential than ever. Windchill, PTC’s powerhouse Product Lifecycle Management (PLM) solution, delivers all three by providing secure, real-time access to product data across disciplines and locations. Companies stand to reduce costs, speed innovation, and enhance next generation products. PTC’s product lifecycle management (PLM) software, Windchill, lets you do just that. Designed to streamline product development from concept to service, Windchill empowers teams to work smarter, innovate faster, and maintain quality—no matter how complex the lifecycle. But let’s start by answering the basics first: what is windchill?

What is PTC Windchill?

PTC Windchill is a product lifecycle management (PLM) application suite that leverages a consolidated view of product information through multi-system data. It’s a systemic enterprise wide approach to maintaining product and process quality throughout the entire product lifecycle. Released by PTC in 1998, Windchill made its mark as one of the first internet-based PLM platforms. It has since become an industry staple across sectors—automotive, aerospace, electronics, medical devices, and more—supporting over a million users globally.

PTC Windchill PLM software provides a complete functionality dimension to help organizations capture product structures from computer-aided design tools, transform them into full engineering bill of materials (eBoMS), to manufacturing bill of materials (mBoMS), to service bill of materials (sBoMS) all while retaining the linkages between different perspectives on the product. Windchill solutions break down organizational barriers, allowing teams to work faster and more accurately all while reducing time-to-market and cutting costs.

Why Windchill Matters: Core Capabilities that Redefine PLM

When companies are juggling increasingly complex product designs, global supply chains, and regulatory demands, having the right PLM foundation is critical. Windchill provides the structure, visibility, and automation needed to handle this complexity without slowing innovation. Its core capabilities not only keep product data accurate and accessible but also empower teams to make faster, better decisions across the entire lifecycle.

Centralized, Secure Product Data Management

Windchill functions as a single source of truth—consolidating CAD files, BOMs, requirements, and supplier data—all housed in a scalable web architecture. Whether you’re working in engineering or collaborating with external partners, you’ll always have a current, secure view of product information.

Effortless BOM and Change Management

Windchill’s dynamic Bill of Materials (BOM) management enables inline editing, structural comparisons, and variant configuration for agile product planning. And with built-in Engineering Change Management (ECM) workflows, you can automate review processes, approvals, and compliance documentation to speed up time-to-market and reduce errors.

Workflow Automation and PLM Collaboration

With task and role-based apps, Windchill supports intuitive collaboration for both expert and casual users. From manufacturing to service teams, everyone can access relevant data through task-specific interfaces without over-customizing the system. This makes handoffs smoother and ensures alignment across functions.

Scalability and Deployment Flexibility

Whether deployed on-premises, in a private cloud, or via Windchill+ SaaS, the platform scales with your needs. Organizations benefit from streamlined upgrades, uptime, and strong compliance controls.

Elevating PLM: AI-Ready Product Development

Windchill isn’t just about data—it’s about intelligent data. By housing consistent, accessible product information, Windchill forms a foundation for AI-powered innovation. That means better decision-making, automated routine workflows, optimized resource use, and faster design improvements.

Key Benefits at a Glance

For many organizations, the true value of a PLM system comes down to the tangible benefits it delivers day-to-day. Windchill is designed to make collaboration easier, processes faster, and information more reliable, no matter how large or distributed your teams may be. By looking at its benefits side by side, it becomes clear how Windchill helps manufacturers overcome common product development roadblocks.

| Benefit | Why It Matters |

| Real-time Collaboration | Unified access enables cross-functional teams to deliver faster. |

| Data-Driven Quality | Reduced rework and improved product reliability. |

| Accelerated Delivery | Configurable workflows and automation streamline processes. |

| Agility & Resilience | Scalable deployments and open integrations help businesses adapt. |

| AI Readiness | Structured data enables machine learning for innovation. |

Core Windchill Capabilities

Beyond the big-picture advantages, Windchill delivers a deep set of tools that tackle the nuts and bolts of product lifecycle management. These capabilities are what allow engineering, manufacturing, and service teams to stay aligned—even when managing thousands of parts, configurations, or requirements. By exploring its core features, you can see how Windchill creates a connected, digital foundation for end-to-end product success.

Windchill’s robust feature stack supports even the most intricate development environments:

- BOM Management – Central views, variants, and CAD integrations

- Collaborative Product Development – Enterprise-wide visibility into planning, shop floor, service context

- Change & Configuration – Automated workflows, traceability, and compliance

- Manufacturing Process Management – Digital twin visualization, plant-specific BOMs, and digital quality tracking

- Parts Classification & Variability Management – Efficient search, sustainability handling, and product customization

- Product Data Management (PDM) – CAD data control, versioning, multi-CAD support

- Quality Management – CAPA, audit trails, regulatory oversight

- Supply Chain Collaboration – Real-time supplier workflows and transparency

Windchill also supports industry-specific packages—PDMLink, MPMLink, ProjectLink, Compliance, Cost, FRACAS, FMEA, and more—so your team can tailor the platform to its use case, from reliability analysis to technical documentation.

Example Use Case: Digital Thread with IoT Integration

PTC’s integration of Internet of Things (IoT) with Windchill closes the loop between product data and actual performance in the field. That enables real-time error reporting, role-based insights, and proactive maintenance or design improvements—putting reliability right in your development cycle.

What problems does Windchill solve for engineering and manufacturing teams?

Windchill addresses persistent issues like data silos, manual hand-offs, and version confusion by providing a single source of truth for product, CAD, BOM and change data. This unified platform helps engineering and manufacturing teams reduce errors, minimize rework, and accelerate time-to-market. By enabling concurrent workstreams and real-time visibility, Windchill supports efficient collaboration across disciplines.

Who uses Windchill and what industries benefit most from it?

Windchill is widely used by discrete manufacturing enterprises including automotive, aerospace & defense, industrial equipment, high-tech electronics and medical device companies. These industries benefit most because they deal with complex product structures, rigorous compliance requirements, and long lifecycles. In these areas Windchill excels. The solution supports both global, multi-site deployments and intricate configurations, making it a strong fit for manufacturers handling complexity and scale.

Is Windchill only for large enterprises, or can small-to-mid-size companies use it too?

While Windchill is known for enterprise-scale capabilities, its modular architecture and cloud delivery options make it accessible to small and mid-sized manufacturers as well. Smaller companies can leverage core functionality like product data management, version control and change workflows without the overhead of full enterprise deployment. As their needs grow, they can incrementally add modules and scale into broader PLM roles.

What are the main components or modules in Windchill?

Windchill consists of foundational modules such as product data vaulting, BOM & change management (PDMLink/PDMLink+), manufacturing process management (MPMLink), quality and compliance (QMS), service information management, and variant/configuration management. Additional modules include extensions for aerospace & defense data, risk & reliability analytics, and digital thread interoperability. These components allow organizations to tailor their PLM deployment to specific functional needs while leveraging a unified platform.

How does Windchill support digital transformation initiatives?

Windchill acts as the backbone of the “digital thread,” connecting engineering, manufacturing and service systems by enabling consistent, trusted product data across the lifecycle. It links to ERP, MES, CAD, IoT and analytics tools, enabling companies to move from isolated applications to integrated, data-driven workflows. By unlocking real-time visibility and enabling downstream usage of design data (such as in service or production), Windchill helps manufacturers transform operations and accelerate innovation.

What are the key features of PTC Windchill?

Key features of Windchill include a central data repository for CAD and business objects, automated workflows for change management, BOM management across engineering/manufacturing, variant/configuration support, role-based access and real-time collaboration. The platform also offers advanced visualization, reporting, document control and integration APIs for enterprise systems. These features combine to reduce errors, improve productivity and enable more agile product development.

How does Windchill improve collaboration across engineering and manufacturing teams?

Windchill enables cross-functional teams to access the same up-to-date product data, drawings, BOMs and workflows regardless of geographic or functional boundaries. With change notifications, task management and configurable role-based portals, manufacturing, sourcing, and service can work in parallel with engineering. This shared visibility and process alignment reduce delays, mis-communication and hand-off errors, enabling faster and more synchronized product delivery.

Does Windchill support document and version control?

Yes, Windchill provides comprehensive document management and version control capabilities, enabling controlled access, historical tracking, check-in/check-out workflows and secure archiving of product documents, CAD files, specifications and more. These capabilities ensure that all stakeholders are working from the correct version of data, audit trails are maintained and regulatory requirements around document governance are supported.

What security features does Windchill offer to protect product data?

Windchill includes role-based access controls, permissions model, encryption in transit and at rest, audit logging, and customizable security policies to protect sensitive product information and IP. Multi-site deployments are supported with secure federated architectures and authentication mechanisms (such as SSO and LDAP) to maintain governance across global teams. These features help ensure that only authorized users can view or modify data and all changes are tracked.

How does Windchill enable compliance and traceability in regulated industries?

Windchill provides traceable process management and audit-ready records of engineering changes, version histories, approvals, manufacturing effectivity and document revisions. Modules such as QMS and audit management support corrective and preventive actions (CAPA), non-conformance tracking and regulatory reporting. All of these outcomes are critical in industries like medical devices, aerospace or defense. By capturing who changed what, when and why, Windchill supports downstream compliance with standards such as ISO 9001, FDA 21 CFR Part 820 and AS 9100.

What APIs or data exchange capabilities are available in Windchill?

Windchill offers REST and SOAP web services, a comprehensive connector suite (ERP Connector, MES integration), configurable workflows, and open APIs to import/export data, integrate with enterprise systems and automate processes. These capabilities enable companies to connect Windchill with ERP, MES, IoT platforms and analytics tools. This ensures product data flows seamlessly across the enterprise ecosystem.

Getting Started with Windchill

Adopting a new PLM system can feel overwhelming, but Windchill is built with flexibility in mind. Whether your business is just beginning to formalize its processes or scaling globally, the platform can be tailored to fit your immediate needs while leaving room to grow. Getting started is about choosing the right deployment model, identifying quick wins, and building momentum for long-term digital transformation.

Here’s how you can begin:

- Define your deployment preference: on-prem, cloud, or hybrid.

- Identify key use cases—change management, BOM governance, quality processes.

- Engage implementation experts (like EAC) to configure, integrate, and train your team.

- Leverage SaaS tools like Windchill+ for faster time to value with built-in cloud benefits.

Next Steps with Windchill

So, what is Windchill? It’s much more than PLM—it’s the digital backbone that unifies product data, processes, and people across your organization. With modern deployment options, robust feature breadth, and readiness for AI, PTC Windchill equips manufacturers to innovate confidently, reduce cost, and accelerate delivery—all while maintaining quality and control.

Want to see an example of how Windchill software is used? See how Virnig Manufacturing uses PTC Windchill to change the way their data is delivered within their organization.

Already using Windchill and need help with admin and support? Check out our Alliance Program, provided to our customers for on-going technical support, business process consulting, and mentoring services on a monthly basis.

Explore what Windchill can do in our webinar, “Go Beyond Data Management with Windchill“.

Manufacturers always try to find a ways to streamline processes and ‘do more with less.’ It drives success in a world full of competition. One way organizations do this is by reducing process complexity with powerful product life cycle management (PLM) or change management software. Connecting your team directly to live operational data increases efficiency in all departments and allows your organization to save money and manufacture products faster.

EAC Product Development Solutions has partnered with PTC, the world’s product development technology leader, to bring organizations the products and services that they need to succeed in their industry. As a PTC Solutions Provider, we provide the maintenance, support, configuration, and training you need to implement change management software as easily as possible.

PTC Windchill Data Management

If you’re looking to do things like keeping better track of files, create and store Bill of Materials (BoMs), put CAD models and drawings in one place, eliminate the risk of two individuals working on a file at the same time, or secure your data without burdening IT – you’re looking for PTC Windchill.

PTC software – specifically Windchill – is a complete PLM solution that provides capabilities such as:

- Bill of Materials (BoM) Management (EBoM, SBoM, MBoM)

- Configuration and Change Management

- Requirements Capture Management

- Early insight into product quality, reliability, and risk

- Efficiently making product variations with a structured platform

- Product Data Management

- Collaboration across all departments with accurate, up-to-date information

- Seamless software integration and defining standards

PTC Windchill is a PLM solution that provides a smooth transition from design to manufacturing with universal access to all critical product data information so that the process isn’t fatigued with delays.

PTC Windchill, Change Management, eBoM Case Study

ALM Positioners, a leading manufacturer of positioner lifts located in Rock Island Illinois, needed PTC Windchill. The company offers unique, customizable weldments and assemblies that require a lot of CAD models and other product information from engineering before manufacturing even begins. Due to extensive product customization and configuration depending on the needs of their customers, ALM needed a better solution to manage product data. They were drowning in paper files – a lot of which had outdated information.

EAC’s implementation team helped ALM Positioners transition to a digital workflow using PTC’s Windchill software. Windchill helped ALM save up to 4 hours per project by integrating EBoMs and MBoMs into their ERP system.

Watch the ALM Case Study on PTC Windchill to see how it has consistently proven to be a leader in the industry and outperformed competitors when it came to product lifecycle management.

Part II – (You can read part 1 here) Evolving your BoM strategy, tools, and abilities. “EBoM vs. MBoM” transforms into “EBoM integrates with MBoM.” This integration includes associativity to one another, time saving tools, elimination of error prone manual steps & more.

Imagine eliminating the common disjointed processes, additional time, and error prone manual steps involved in the creation of downstream BoMs from Engineering into Manufacturing, Production and Service management.

Concepts & examples such as Manufacturing Bill of Materials (MBoM) are shown below, all under one system, integrated & associated, and created with a single click. Then they’re easily edited to meet downstream BoM needs.

BoM creation can be streamlined & improved by associatively creating downstream BoMs (S or M or other) and eventually, connecting them to your ERP system. For now, we’ll focus on the first step of this business transformation concept; the creation of the second, or downstream M or SBoM, starting with a simple EBoM example, created in minutes, and easily viewed & tracked.

Who should be involved in this topic at your company? Ideally, your Configuration Manager role should be leading or heavily involved in this process.

The starting point & tool is PTCs Windchill and your willingness to change & improve.

Once your CAD data is ready to check into Windchill, there is an option (check box) to auto-associate the EBoM to a downstream BoM such as an MBoM. It is a 1:1 relationship for starters. Options can branch out from here into many CM (Configuration Management) directions. Such as multi-level BoM management, uses, visualization and more.

Once created, you can manipulate & edit the default 1:1 downstream BoM to your needs; adding bulk items, manufacturing specific sub assemblies, (build throughs) even new service end items. You can also flatten out an EBoM to meet assembly or production needs. BoM items such as adhesive, lubricant, paint or coatings, packaging items, all things that typically are not on an EBoM, can and do belong on the M or SBoM.

If this fits your company’s needs? consider using Windchill’s auto-associate feature.

This article covers a couple examples. If this is not deep enough…here are even more tools to consider. Topics such as creating associated manufacturing instructions, work instructions, work plans and more. Change Management is shown as reference only, it is an optional element of Windchill for another blog.

There are many options to this topic, these are common examples that fit a lot of needs and is considered a starting point.

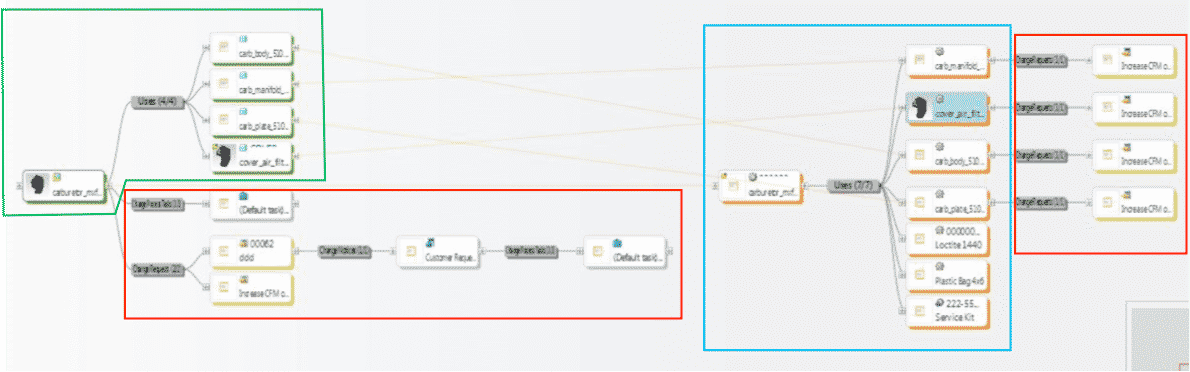

1stexample shows all BoM & change components all connected in one system vs. manually done in silo fashion, which is industry’s most common method today. These examples are shown in PTCs Windchill reference viewer tool, which ties all related objects into view for easy visibility with just a few clicks.

- 1. EBoM structure (highlighted in green)

- 2. Change requests, notices and tasks (highlighted in red)

- 3. MBoM structure (highlighted in blue) with their own, or connected Change Management Requests, Notices & Tasks

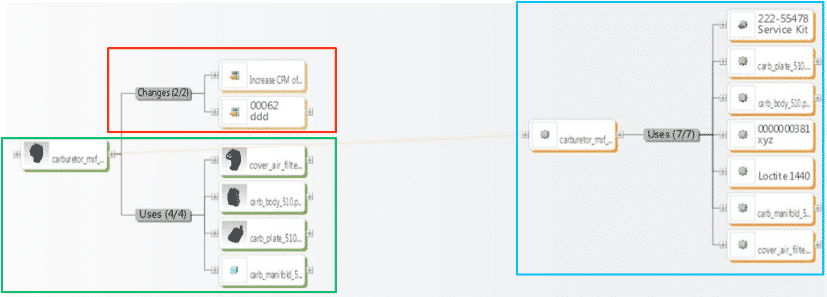

2ndexample shows an EBoM, SBoM (Service Kit in this example), with a saleable end item service kit, as well as components for service or manufacturing BoMs. It also shows Changes, these can also be created, edited, routed, approved or rejected, and even include the SBoM if need be.

Please connect with EAC to learn more, to discover your company’s transformation opportunities with an assessment, maybe see a demo, or attend a webinar. The goal is to help your company transform how you design, manufacture, connect to and service your products.