We’d like to share some news with you in our new youtube video we’ve nicknamed the ‘3D Printing Show’. Anthony Bayerl, Director of Marketing, and Lauren Adey, Additive Manufacturing Specialist bring you the latest news in the 3D printing industry.

There are a lot of exciting things happening including new product announcements, tips and tricks, product updates, discounts, and promotions.

Watch our video to learn about the latest additive manufacturing news.

New 3D printer called the ‘Replicator’ makes 3D print in minutes, with almost no wasted material

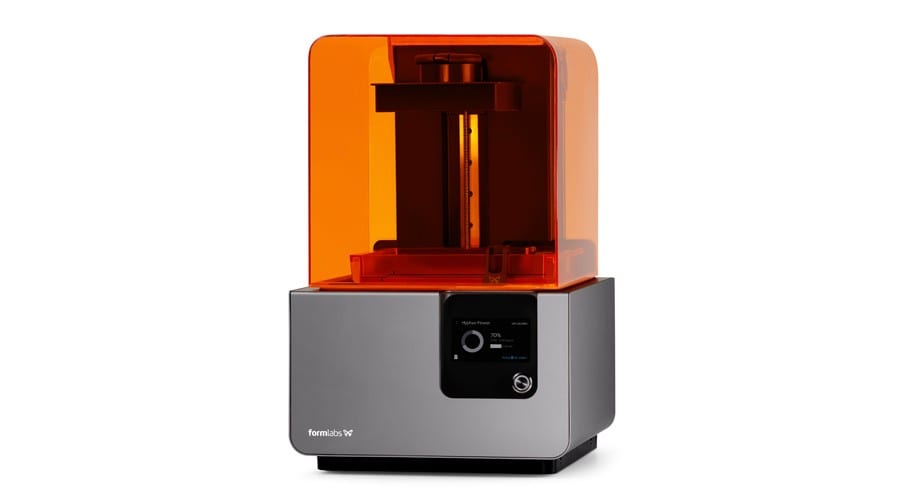

Stereolithography (SLA) desktop 3D printers, such as the Form 2 from Formlabs, creates 3D prints with photopolymer resin cured with a UV laser and built layer by layer. Structural lattices are created with extra material to ‘fill in’ necessary skeletal-like structures for support to continue to build the part or prototype.

UC Berkeley researchers discovered a new 3D printing technique that transforms liquid on a rotating cylinder to a solid with carefully projected rays of light – without having to waste any extra material in the 3D printing process.

Hossein Heidari, a graduate student at UC Berkeley and co-first author of the work says, “Our technique generates almost no material waste and the uncured material is 100 percent reusable. This is another advantage that comes with support-free 3D printing.”

The researchers named the 3D printer the “replicator” after the Star Trek device that instantly materializes any object. This new technique creates 3D prints in a matter of minutes compared to other techniques that could take hours.

We can’t wait to see where these UC Berkeley researchers take this new zero-waste 3D printing technique!

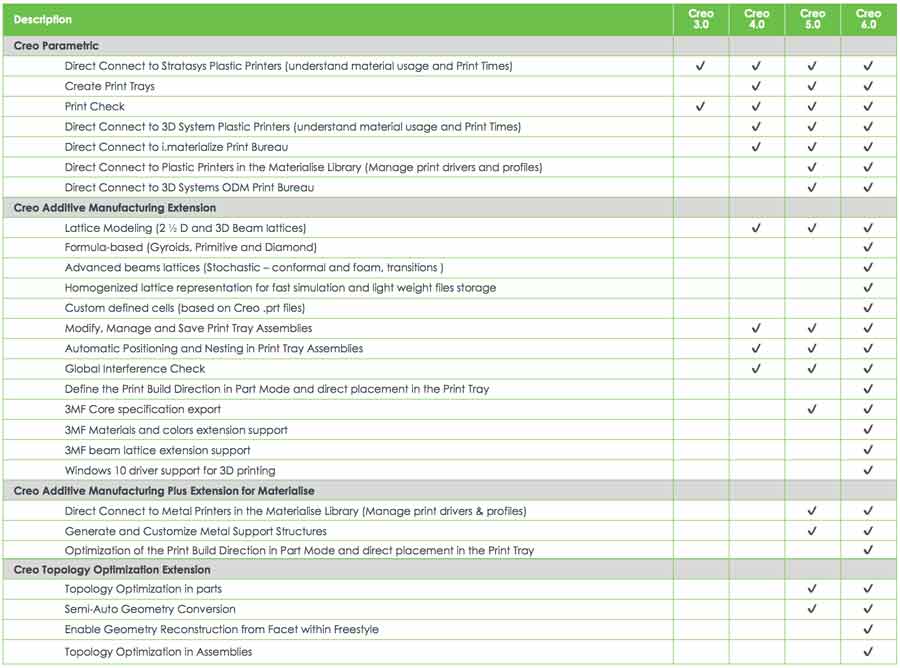

Creo 6.0 makes software updates to support new lattice structures, build direction, and topology optimization

With the release of Creo 6.0, PTC has updated the additive manufacturing capabilities to design with lattice structures, build direction definition, and slicing. Designing your CAD models with Creo allows you to design, optimize, validate, and run a print-check all in one environment – which means you can send your file straight to the printer when you’re done with your final design. Metal printing capabilities cover around 70% of the metal printers that are sold in the market.

Creo Parametric includes the 3D printing capabilities to directly connect to your printer. These capabilities are included in Creo 5.0 and Creo 6.0.

The Creo Additive Manufacturing Extension includes design abilities such as lattice modeling, advanced beams lattices, custom-defined cells, and defining print build direction. These capabilities are included in the Creo Design Advanced Plus package or you can purchase the extension separately.

The Creo Additive Manufacturing Plus Extension for Materialise includes capabilities to directly connect to metal printers, customize metal support structures, and optimize build direction. These capabilities are included in the Creo Design Premium Plus package or you can purchase the extension separately.

The Creo Topology Optimization Extension includes capabilities to use topology optimization in parts and assemblies and enables geometry reconstruction function. These capabilities are included in the Creo Design Premium Plus package or you can purchase the extension separately.

How to wash your parts & prototypes with the Form Wash

We’ve discussed ways that you can better use the products you already own – this time, we’ve got a tip coming from one of our customers – Jeff Martin, an Application Engineer from Colder Products (CPC) on how to clean your parts and prototypes with the Form Wash. Check it out in our blog here.

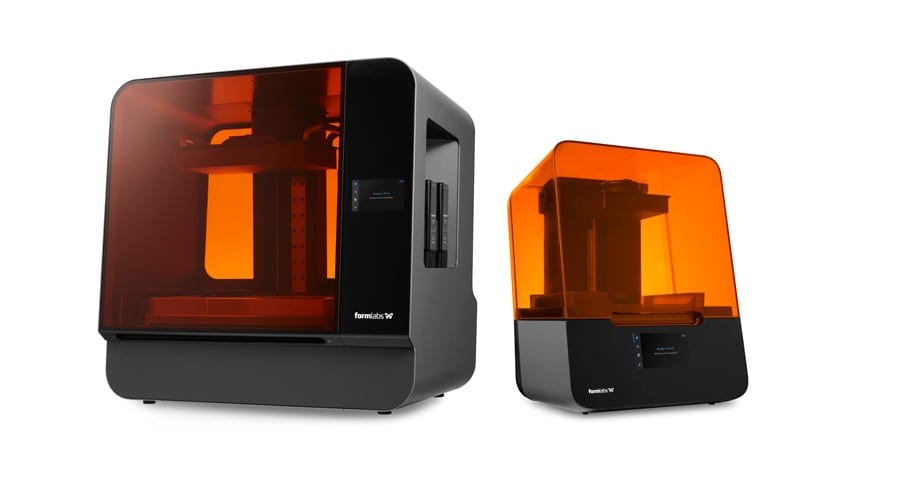

New Formlabs 3D Printers: Form 3 and Form 3L

Formlabs has released the Form 3 and the Form 3L! The Form 2 uses the stereolithography (SLA) process whereas the Form 3 and Form 3L uses a process called low force stereolithography (LFS) – meaning that the printers literally use lower forces to create easier support removal and more precise detail and surface finish. Read our blog Formlabs Releases New 3D Printers using LFS Technology to learn more about SLA and LFS technology.

Form 2 Discounts!

The Form 2 desktop SLA 3D printer has dramatically decreased in price (from its previous price of $3499) to $2850. We ARE still selling the Form 2 and will support those that want to purchase an already affordable 3D printer at a more affordable price.

Contact Lauren Adey, our Additive Manufacturing Specialist, to take advantage of these special deals!