- Robust computer vision that allows experiences from the widest range of target types including objects, models, images, surfaces, multi-targets, cylinders, and VuMarks.

- Cross-platform development that supports Android and iOS ARkits

- Vuforia Fusion enables easy optimization of AR experiences across a range of devices

- Seamless integration with industry-leading complementary design and modelling applications

- Broad community of developers with deep Vuforia Engine experience

Evaluating potential Augmented Reality (AR) solutions for manufacturing can quickly become overwhelming when you consider testing out product trials and going over pricing details.

A new IDC Report, How AR Drives Real-World Gains in Service, Training, Sales & Marketing, and Manufacturing, states, “AR technology is here and now, and companies of all shapes and sizes are utilizing it to change the way work gets done and to drive better outcomes.”

This article talks about the top proven industrial Augmented Reality Solutions and exactly what they can do for your industry.

The most widely used platform for AR development: Vuforia Engine

Today, over half a million developers have chosen the advanced performance and cross-platform reach of Vuforia Engine, making it the most widely used platform for AR development on the planet.

Why is this considered to be the most flexible tool for AR development? Because it delivers robust and precise AR experiences in a variety of environments. This AR Engine is a powerful cross-platform software enabling branded AR experiences for both new and existing applications to be deployed in leading app stores.

It lets developers freely build branded AR experiences for new or existing applications and supports AR devices such as phones, tablets, headsets, and smart glasses across leading platforms to reach the largest audience.

By using Vuforia Engine, developers can easily add advanced computer vision functionality to Android, iOS, and UWP apps, to create AR experiences that realistically interact with objects and the environment.

The Vuforia Engine Library also contains technical documentation to help developers be successful as they create AR applications.

With Vuforia Engine, AR developers can harness best-in-class computer vision capabilities, to detect and launch a variety of target types. This AR engine also is equipped with broad support for leading modeling platforms and user applications.

Features and capabilities of Vuforia Engine

Vuforia Engine comes with many distinguishing features and capabilities. These include:

Discover all of the unique features of Vuforia Engine here.

What are Vuforia Engine applications used for?

Vuforia Engine AR applications are best used for:

- High-end production of custom AR applications

- Developing customer facing applications that require superior product values

- Experiences that require sophisticated and flexible target recognition

- Elevating brands with complementary apps

- Integration with industry-leading design and modeling application

The best AR Authoring Solution: Vuforia Studio

Vuforia Studio is an Augmented reality authoring solution that lets you quickly build scalable AR experiences. Vuforia Studio is an augmented reality authoring solution that helps you rapidly build AR experiences.

Vuforia Studio enables efficient, cost-effective authoring of industrial AR without the need for in-depth programming or skilled programmers.

This AR solution helps designers, engineers, and technical publication end users author and publish scalable AR experiences that transform manufacturing, service, and training processes.

You can now experience features from the tool that have a robust and visual interface – easy for design file importing and ubiquitous viewer support.

How does Vuforia Studio work?

Vuforia Studio is a drag-and-drop authoring environment that enables industrial content creators to use existing 3D CAD and animated sequences.

This AR authoring tool leverages real-time IoT and business systems data and allows users to access and view experiences from a single app.

Its simple, easy-to-use drag and drop interface allows content creators with no prior coding knowledge to get up and running quickly.

Vuforia Studio features and capabilities

Distinguishing AR features and capabilities that come with Vuforia Studio include:

- Visual authoring environment

- Easily import CAD and animated sequences

- Native support for IoT data

- Scales to support global AR deployments

- Certified support for hosting and on-premise deployments

- Powerful spatial and model tracking

- Out-of-the box support for mobile and head worn devices, including Microsoft HoloLens and HoloLens 2

What are Vuforia Studio applications used for?

Vuforia Studio is best used for:

- 3D digital content overlaid on real-world equipment to provide contextual knowledge

- Rapid development of immersive training and instruction content

- Reusing existing CAD models and sequences to create step-by-step work instructions

- Visualizing real-time IoT data to provide operating conditions and equipment performance

- Full-scale visualizations that enable walking around and seeing products

- Accurate identification of spare parts

- Scaling across products, configurations, devices, and geographies.

The Best AR Remote Assistance Software: Vuforia Chalk

Vuforia Chalk is a powerful AR remote assistance and guidance application that helps experts and technicians solve problems more effectively.

You can think of it as an easy to deploy, mobile-based guidance and collaboration AR tool.

Vuforia Chalk enables pairs of mobile device users to collaborate around a shared view of objects and environments, with smart 3D annotation capabilities.

This allows senior experts to virtually share knowledge with junior colleagues and removes geographical barriers to collaboration. Picture this – if you’re a service technician in Nebraska, you can be helping someone located in Oklahoma just with the power of your fingers on your mobile device using the Vuforia Chalk app.

Vuforia Chalk combines advanced augmented reality with real-time communications to connect a field technician with an expert so that the expert can see and discuss the situation in the field.

With this powerful AR remote assistance application, a technician or an expert can draw digital annotations (using one’s finger on the screen) that accurately anchor to physical objects, allowing the expert to guide the technician through the process, step-by-step.

It allows experts and technicians to accurately markup live views, highlight details, and guide multi-step solutions.

Essentially, this AR tool empowers field technicians with instant “over the shoulder” field support to finish every jobs and tasks without delay.

The software helps organizations increase service quality while reducing repeat maintenance or repair visits – providing frontline workers with access to service information in a completely modern way.

Vuforia Chalk makes it easy to guide service and troubleshoot situations that may not be covered in training or service manuals.

Vuforia Chalk features and capabilities

Vuforia Chalk is paired with many distinguishing features and capacities that include:

- Zero development requirements- this AR tool can be provisioned in minutes and used immediately

- Connection links – Chalk users can connect with mobile devices using a video link. This allows the users to share views of the equipment or environment. Each user can draw on their screen to annotate the shared view.

- Advanced annotation that can be locked onto targets- this allows users to move around objects and annotations with 3D spatial recognition.

- Chalk views can be paused- this allows user to easily draw multi-step instructions over objects.

What are Vuforia Chalk applications used for?

Vuforia Chalk makes it easy for remote experts to provide remote over-the-sholder guidance to speed troubleshooting. Using either a mobile device or tablet, remote experts can connect to technicians and annotate on their shared view.

Vuforia Chalk is best used for:

- Enabling remote, virtual assistance between technicians and experts

- Collaboration between physically dispersed colleagues and teams

- Building lightweight AR pilots that prove value fast without development resources

Transform work instructions with Vuforia Expert Capture

Vuforia Expert Capture is the fastest and easiest way to create step-by-step instructions that help frontline workers get their job done accurately and efficiently.

Vuforia Expert Capture gives content creators and subject matter experts step-by-step instructions with rich media content, text, and audio to improve workforce productivity, quality, safety, and compliance.

It is an out-of-the-box AR solution that features drag and drop AR content creation for industrial enterprises looking to rapidly document expert knowledge and then easily scale that knowledge to new or redeployed workers as hands-on training or task guidance.

This tool provides an easy way for experts in your organization to record video procedures and instructions to others using augmented and assisted reality.

Features of Vuforia Expert Capture

There are many distinguishing features and capabilities of Vuforia Expert Capture some of which include:

- The ability to rapidly author AR instructions without CAD data, pre-existing assets or development efforts.

- Easy to use templates that simplify and accelerate creating and publishing AR content

- Content editing and publishing is in a secure, web-based environment

- The ability to automatically deliver optimized content across a variety of supported devices.

What are Vuforia Expert Capture applications used for?

Vuforia Expert Capture is best used for:

- Capturing procedures and tasks from senior experts

- Servicing and working with factory floor machines that lack relevant CAD data, or instances where documentation is unavailable or of poor quality

- Documenting multi-step procedures that take place in multiple locations

- Ensuring compliance through documentation of standard operating procedures (SOPs)

Why use Vuforia products?

Vuforia makes AR content easy to create and deliver widely to the enterprise to help improve efficiencies, reduce downtime, and enable safer and more productive workers.

With the industrial Vuforia AR platform, organizations can build custom experiences from the ground up, or rapidly create and scale enterprise-ready industrial AR experiences without writing any code using Vuforia Studio.

Whether the requirement is a custom solution or the ability to deliver rapidly, Vuforia delivers powerful, game changing industrial AR technology.

Looking to to get started with AR? Contact us.

If you…

- Need help evaluating potential manufacturing AR solutions, product trials and pricing details

- Are ready to learn how to transform your operational efficiencies, output, and quality with AR

… then get in touch with a Vuforia AR Specialist to answer questions and schedule your demonstration. Our AR experts can help you take the next step in your journey.

This is a guest blog written by Jonathan Lang from PTC – you can find the original blog post on PTC.com.

While augmented reality (AR) and computer vision technology are making it possible to wear digital clothing, the concept of a digital thread offers a powerful new framework to unlock data accessibility and add new analytical and decision-making capabilities to your business.

The digital thread is proven to drive speed, agility, and efficiency in the products, operational processes, and related worker tasks.

Let’s take a look at how:

What is a digital thread?

Digital threads seek to create homogeneity and simple universal access to data. They follow a single set of related data as it weaves in and out of business processes and functions to create continuity and accessibility.

A digital thread can be created for many different entities and processes. Most commonly, a thread of a product follows the lifecycle from design inception through engineering and product lifecycle management, to manufacturing instructions, supply chain management, and through to service histories and customer events.

This thread enables enterprises to anticipate and effectively communicate bi-directionally up and down stream of where the product is in its lifecycle, ensuring all participants utilize the most current data and can react quickly to changes or new insights.

Similar threads are emerging for entire operational environments and processes – and even worker tasks and workflows – due to the prevalence of digitization across the value chain driven by technologies like IIoT, AR, MES, and others.

Why do I need a digital thread?

Data discovery accounts for a lot of workers’ time. Integration of disparate information systems in retrospect is costly and jeopardizes goals, deadlines, and market opportunities. A 2018 study by IDC of more than 400 professionals who work with data found that 37% of the time they spent ‘getting to insight’ was searching for information, while only 27% was used for analysis.

In the age of digital transformation, new data challenges have emerged, and digital threads offer a solution to improve the speed and agility of enhanced decision-making promised by all of this data. They’re about removing bottlenecks and improving transparency and accuracy of critical business information across the value chain.

How do digital threads enable digital twins?

While there are benefits to this continuity across related data sets and activities, the advanced versions incorporate physical world sensor data through IIoT capabilities or through the use of physics-based ‘virtual sensors’. Utilizing these physical world proxies of products, processes, and even people and their workflows, AI algorithms can test potential scenarios to find optimization opportunities for a variety of outcomes.

When a digital thread or ‘definition’ of a product or process is applied to a 2D or 3D graphical proxy and real-world data is modeled against it, this is referred to as a digital twin. Digital twin use cases include predictive maintenance and service for products and operational intelligence across an industrial environment.

To achieve a digital twin, a digital thread must first be established. Digital thread is predominantly used to unify and orchestrate data across the lifecycle of a product, from original design, to engineering, manufacturing, operation, and service. This enables product manufacturers to analyze a holistic data set, and ensures that functions across the organization are always working with the most up-to-date information.

With the widespread adoption of IIoT technology, connected worker technology like augmented reality, and increasingly sophisticated MES and supply chain networks, digital threads are quickly expanding beyond products to be the connective tissue enabling operational insights. Woven together into a holistic view of an enterprise across many interrelated processes and functions, the relationship between multiple digital threads is referred to as a digital fabric or mesh.

Even today, digital mesh is forming all around us and will be the foundation upon which we architect and orchestrate digital experiences in the physical world in the future.

To learn more about digital twins, read our blog on how digital twins improve future innovation and product development.

There are many benefits of AR (Augmented Reality or Assisted Reality) and digital work instructions, but the idea of digital transformation can seem overwhelming. This article talks about why many organizations are starting to consider digital work instructions, and the benefits augmented reality (AR) can bring.

As organizations begin to deploy applications at scale, they often realize that AR presents both opportunities and challenges. Creating compelling AR experiences for an enterprise has historically been difficult, limiting the reach of how much and what can be deployed.

Despite the occasional challenges, organizations continue to explore the new possibilities and value AR can bring to service, operations, engineering, and manufacturing.

For starters, if you’ve made a heavy investment in technical publications or technical documentation, odds are you have a lot of content in a multitude of systems and formats such as Arbortext, DITA, or even S1000D. This has most likely occurred over a long period of time and leveraged a lot of resources.

With all the resources, time, and energy put into your technical publications the idea of ‘going digital’ or moving towards ‘digital work instructions’ can be daunting.

So why is there currently so much ‘hype’ about pairing Augmented Reality with service or manufacturing, and what benefits can it bring to your organization?

Well… there are a lot of reasons for taking on digital work instructions, or even hands-free work instructions, that can be projected by a head-mounted tablet, a headset, or even an iPad or cellular device. And quite frankly, there are a lot of practical applications throughout an enterprise that can benefit from up to date content delivery and process/quality control.

Augmented Reality relates to the new workforce

If you look at manufacturing plants, assembly facilities, and at the service world as a whole – these groups of people are aging. This means that the manufacturing skills gap is widening.

In fact, there’s quite a bit of turnover happening which is starting to make it difficult for organizations to find competent, qualified replacements.

Studies show that over the next decade, due to economic expansion and the surge in baby boomer retirement, nearly 3.5 million industrial jobs will be needed, and 2 million are expected to go unfilled.

For instance, if you look at an aircraft assembly worker today, most are going to be older guys and gals. They’re used to doing things with physical resources (such as paper for example).

But if you’re looking to replace one of these retiring workers, your replacement is most likely going to be someone used to consuming his or her information through technology devices like iPads or mobile phones. A bonus, however, is that these individuals are more likely to be very open to new technology such as a head-mounted tablet.

The fact is, in most cases, we are talking about entirely different generations of our workforce. The way they consume, process, and work with new information will be entirely different than veteran-ed workers.

It is in your best interest to get these new-aged workers up to speed as quickly as possible. An excellent way to do that is to use delivery methods familiar to younger generations.

This is one of the many reasons companies have begun to explore augmented reality (AR).

Best-in-class organizations realize the benefit of investing in ways to get new workers up to speed as quickly and efficiently as possible.

AR for field service

Many organizations see “field service” as an excellent starting point to implement AR. There are a lot of time savings for service personnel when you go from paper to digital. This is why companies across the board have made the decision to go into a paperless environment.

The upside of AR is readily apparent when inspecting how someone attempts to execute specific detailed tasks on a shop floor. This almost always involves going back to paper instructions which in turn, takes time and wastes a whole lot of resources; hunting for documentation, going to-and-from workstations to document cabinets, etc. This compounds as workers switch tasks.

Augmented Reality provides cross reference materials

By simply enabling a workforce to digitally access resources, an organization can save time, proactively improve processes, and more effectively manage quality.

Augmented Reality allows workers to very quickly and efficiently cross-reference material and pull up related images, user guides, bulletins, and other content. All without leaving a workstation or job site.

For example, if a service technician was to get lost while using a paper instruction manual and he or she didn’t know the next step, AR provides a solution.

With an augmented experience the service technician can link directly back to technical information to read further into a problem that perhaps wasn’t included on the paper instruction manual or was somewhere else.

AR helps track detailed project status

Because AR is simply a delivery mechanism, it can be configured to interact with multiple databases and content sources. Project and task authentication and sign-off requirements can be delivered to workers through their devices but managed digitally at the edge or within discrete systems.

This means there’s a detailed digital trail of the work that’s been done and being done by each individual service technician.

Therefore, if a service task were to get interrupted, someone else on the team could pick up where the previous technician left off – knowing that the all the steps in the work instructions have been completed and signed off by the last worker.

Process and quality control benefits of AR

Some AR solutions even provide the added benefit of recording the time taken to complete a specific step or entire task. It provides insight into possible areas for training or process optimization.

In other words, it can help an organization notice discrepancies between expectations and execution – ‘as written’ and ‘as executed.’

You open the door to many closed-loop quality control improvements when you have insight into, and a digital signature on every completed task.

Hands-free work environment

Both head-mounted tablets and phones can be operated in a hands-free environment.

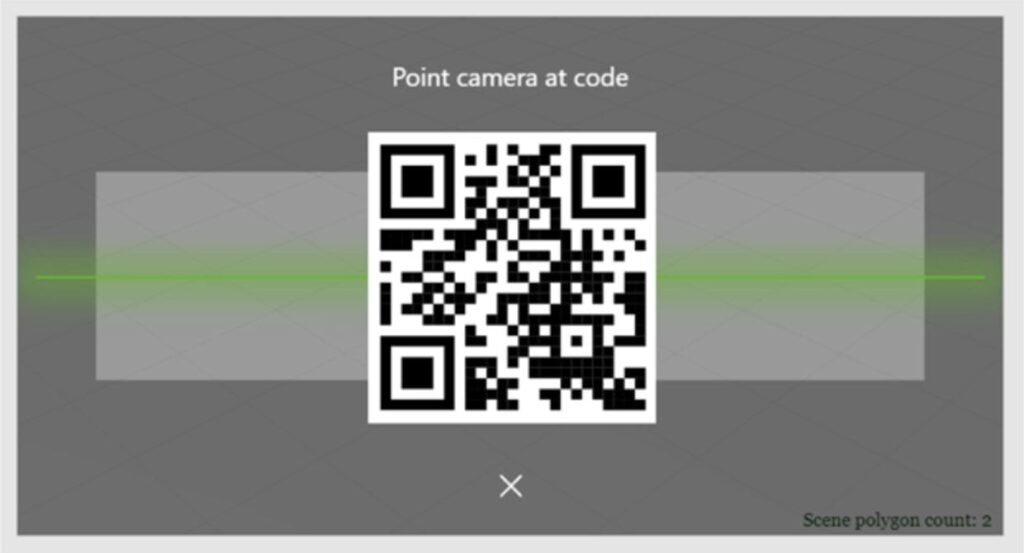

Handheld devices scan activated QR codes to read instructions. This allows operators to maneuver hands-free while the instructions are being read to them.

By using a head-mounted template environment, you can verbally communicate with the instructions on the head-mounted tablet without ever having to look away from work, or wake up a tablet or phone.

The return on investment for AR

The upfront costs are often the most expensive part of this piece of this digital transformation journey. Whether implementing a full-scale enterprise deployment or a proof-of-concept, you’ll often need to lay the same foundation of supporting technology. But it is worth it.

Talk with us if you’d like help figuring out a ballpark investment to get AR going at your company.

The ROI is tangible and real. For instance, AR solutions can easily save a $60,000 fully loaded resource 8 to 12 minutes a day by replacing paper and disjointed processes. That turns into four hours a month, forty-eight hours a year. That’s more than $1,300 per year in savings for every worker. The ROI quickly goes up proportional to the number of users added to the system.

Conclusion

I’ve made my case. But it doesn’t change the challenge I brought up at the beginning of this article. Moving, converting, and re-authoring legacy technical documentation is daunting…

Or is it?

We have a solution. It’s called AR Instruct™. Watch the video below to get an idea of what it is and how it could help you.

AR Instruct™ is an application that takes an existing product, assembly, service, and other technical information (in formats like DITA, XML, Arbortext, S100D, etc.) and dynamically transitions it to be displayed in a digital work environment. We aren’t talking about publishing a PDF on an iPad either.

AR Instruct™ publishes fully interactive experiences complete with voice commands, step management, graphic viewers and all.

You should do two things after reading this article – 1) Request a demonstration and 2) Forward this on to the people in your organization responsible for publishing and managing work and service instructions.

Let’s talk about how technical documentation impacts field service procedures, high costs of inaccurate technical information, the root causes of service failures, and how to achieve high field service productivity and effectiveness.

Many of the fundamental issues in service occur due to inaccurate service information and technical documentation that is difficult to understand.

We have all been in a situation, at least once, that involved failure to deliver a service as promised. Why? It’s because all brands and businesses make promises! But the truth is… service issues happen

When service fails to deliver on promises, or a buyer experiences poor customer service, the result almost always ends with lost customers, canceled subscriptions, and tarnished brand reputation.

The impact of a service failure can be devastating. Let’s talk about the root causes impacting service issues and failures

The impacts of service issues

The greatest influence on service almost always has to do with one thing; technical documentation. By technical documentation I am referring to tech pubs, standard operating procedure documents, service instructions, maintenance manuals, guides, work instructions, procedures, bulletins, etc.

I’m talking about anything and everything that is provided to help assist and guide service technicians. Many of the fundamental issues in service occur due to technical documentation, let’s talk about why.

Technical Documentation and Field Service

Today many field service and manufacturing organizations rely on traditional time-intensive methods to develop and deploy technical documentation such as service procedures, work instructions, guides, manuals, etc.

But the fact is – oftentimes the tech pubs, guides, and manuals that are created, aren’t even read (or in some cases even used) by field service representatives for which they were designed!

In addition, technician instruction manuals and documentation designed to be used in field service are often out-of-date. This is due to the high maintenance and distribution costs to create, maintain and produce continually up-to-date field service documentation.

This issue compounds as products become more and more complex in response to ever increasing customer demands for innovation and customization.

This rise in complex products has resulted in complex service and maintenance procedures, affecting and influencing inaccuracies in technical writing and documentation. As the demand for complex maintenance and service procedures increase, technician efficiency decreases due to more time being spent searching for the correct service information in a format that can be used on the field. This often results in repair and maintenance delays.

When service technicians encounter unfamiliar problems and don’t have reliable service information to solve a problem, the need for repeat service visits increases. There are many major negative consequences from these situations.

For example, a customer might experience equipment downtime. This downtime impacts both the service provider, as it inflates the cost of service, as well as the customer, as they lose productivity.

The high costs of inefficient field service

For you, as a service provider, the consequences of poor service information, complex products, and poor technician efficiency can drastically impact your costs of service in a number of ways.

For starters, let’s assume you work with service contracts. Service contracts often contain elements such as equipment up-time clauses. In the case you were to unintentionally breach one of these ‘set clauses’, it’s fair to assume the organization would face undesirable penalties and costs.

Take a deep breath. All is not lost. The added costs from inefficient service strategies are completely avoidable!

Repeat field service visits also drastically increase business costs. Multiple repeat visits to service products quickly increase costs and become very expensive. This is why many organizations seek to avoid repeat service visits at all cost.

A rarely considered cost-driver for service stems from difficulties comprehending poorly written, inaccessible, and out-of-date technical documentation.

When service technicians are unable to easily identify which spare parts are required, they often order multiple parts in hope that one will be correct. This results in high part returns, and handling costs. Not to mention, the need to hold more parts in stock from inflated orders (the bull whip effect), also affects parts inventory.

The skills gap is also increasing the cost of inefficient service.

“Faced with continuing economic expansion and retirement of baby boomers, the US manufacturing industry is looking at a potential shortage of 2.4 million workers in the next decade.” – 2018 Deloitte & The Manufacturing Institute skills gap study

To put it in perspective, a large portion of our workforce is approaching retirement soon. This is causing the skills gap to widen. With the loss of tribal knowledge, access to consumable expert knowledge becomes increasingly necessary.

New and inexperienced technicians have repeat service visits which cause an organization to face higher training costs, while overburdened experienced staff members are forced to train and pick up the slack for newer employees.

All of these things impact customer satisfaction. These conditions damage service reputations for both an organizations product, as well as, service contracts. Most importantly, all of these scenarios impact an organizations ability to retain customers and garner repeat business.

Sometimes you need to break down the barriers between product development and operations.

How to gain high service productivity and effectiveness

In order to obtain high technician productivity and effectiveness you must re-evaluate your service methods and procedures

Increase technician comprehension with accurate AR work instructions

To increase technician comprehension, look into concepts to create accurate, in-context augmented reality (AR) work instructions that overlay digital information onto a physical product.

Establish accurate part identification

Consider implementing accurate AR experiences so part identification, replacement and ordering are easy and accurate.

Enable remote real-time work instructions

Enable expert technicians to give remote, real-time guidance on physical objects using assisted reality tools like Vuforia Chalk.

All of these help service organizations create a more flexible, agile, workforce. These changes result in increased equipment uptime and productivity. They result in happier customers and more empowered workers.

Most importantly – you can start implementing these benefits today. All the technology currently exists. We would love to work with you and your organization to understand your service operations goals and map a path forward.

Augmented Reality (AR) and Assisted Reality for digital work instructions have become a growth driver, or at least consideration, for many industries.

Yet moving everything from paper or ‘digital hard-copy’ to digital AR experiences seems to be a daunting task for large and small organizations alike.

The truth is, there are many ways to incorporate augmented reality into service, but many of these can disrupt current processes and be a challenge to implement.

This is why, our company (EAC Product Development Solutions), developed and created an easier way to make service information more accurate, relevant and accessible.

It allows you to easily deliver the content behind AR instructions, manuals, and guides to digital devices such as tablets, head-mounted displays, or cell phones.

Implementing AR for service should be easy. That is why we created a better way.

The tool is called AR Instruct – It easily connects traditional technical publication content to the AR world.

Digital Work Instructions & AR Instruct

AR Instruct enables “hands-free” execution of work instructions using the latest immersive technology including: Augmented Reality, Assisted Reality, and Mixed Reality.

Our AR solution works as an AR publishing engine that repurposes existing S1000D, Arbortext, or XML, technical publication content and simplifies the transition to hands-free and mobile paperless instructions.

The best part? AR Instruct requires no content re-authoring and no content rebuilding. It’s really that easy.

AR Instruct can even dynamically publish up-to-date work instructions from the latest document revision on your server. This will ensure accuracy, compliance, and quality.

Watch the video below to get a quick and easy introduction to AR Instruct.

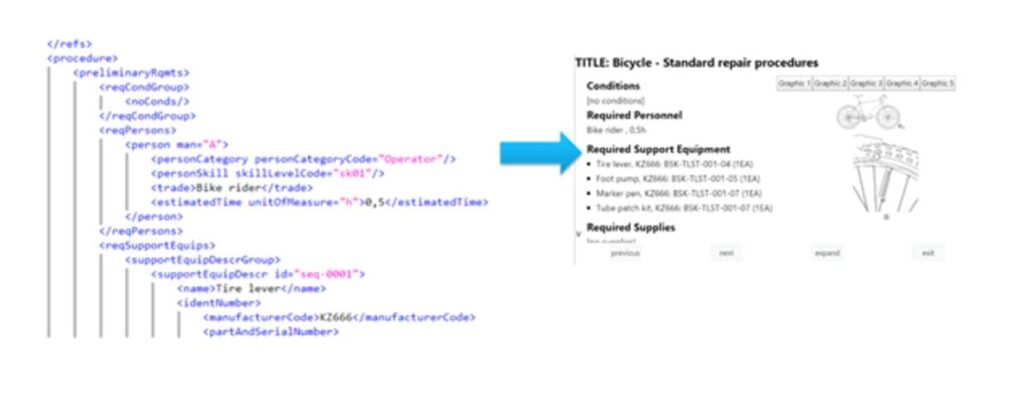

How does AR Instruct work?

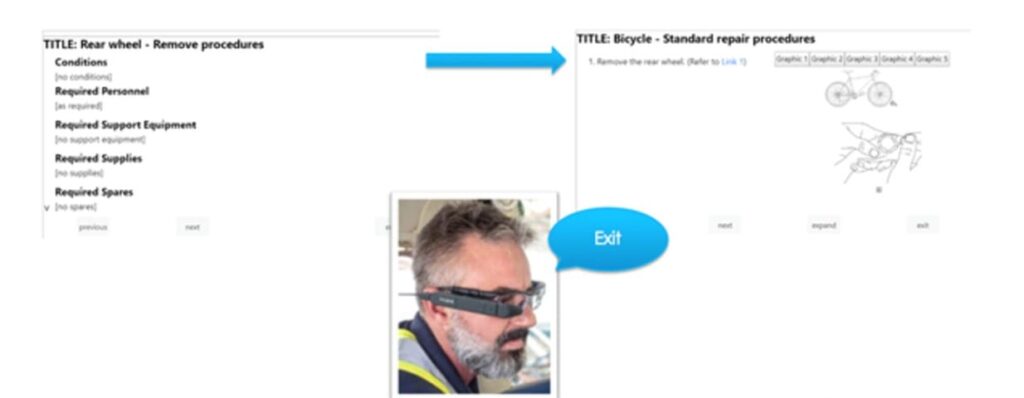

A Service Engineer scans a work order QR code to locate relevant service procedures.

Our AR publishing engine, AR Instruct, retrieves XML content and dynamically formats it for AR viewing. This requires no manual publishing at all.

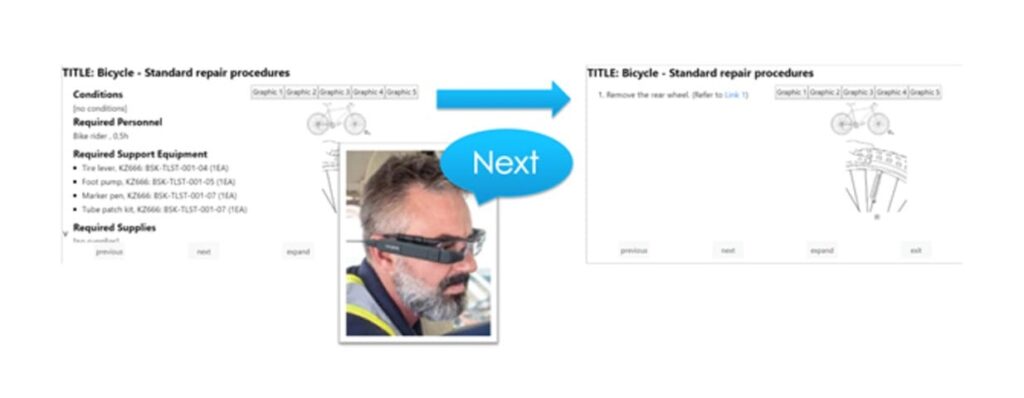

Using a digital device like a Vuzix or RealWear, the service engineer can navigate the AR content hands-free with voice commands.

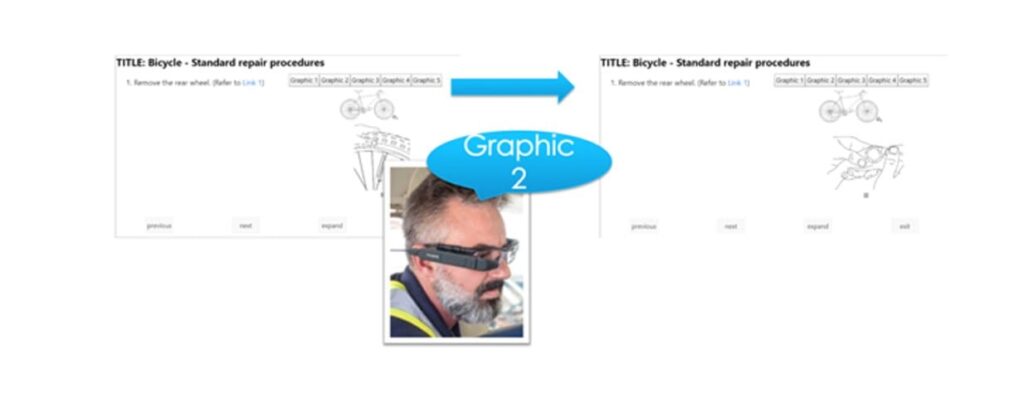

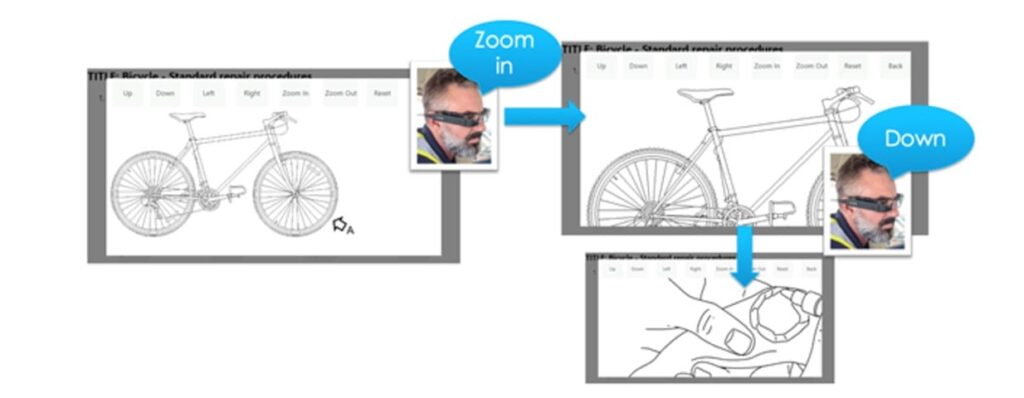

The Service Engineer can inspect each associated technical graphic related to the product.

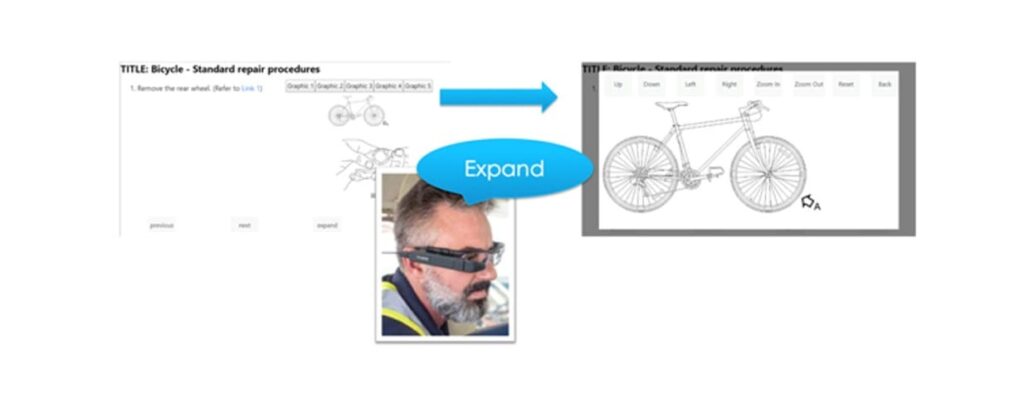

The Service Engineer can also expand any technical graphic or content for enhanced viewing.

With the AR Instruct graphic viewer, the Service Engineer can pan and zoom any image by using voice commands. All buttons he or she sees are “readable” as voice commands.

Using voice commands, the Service Engineer can navigate links to cross-referenced steps or procedures.

Once the Service Engineer is done with the cross-referenced content, he or she would be able to return to where they left off in the original service procedure.

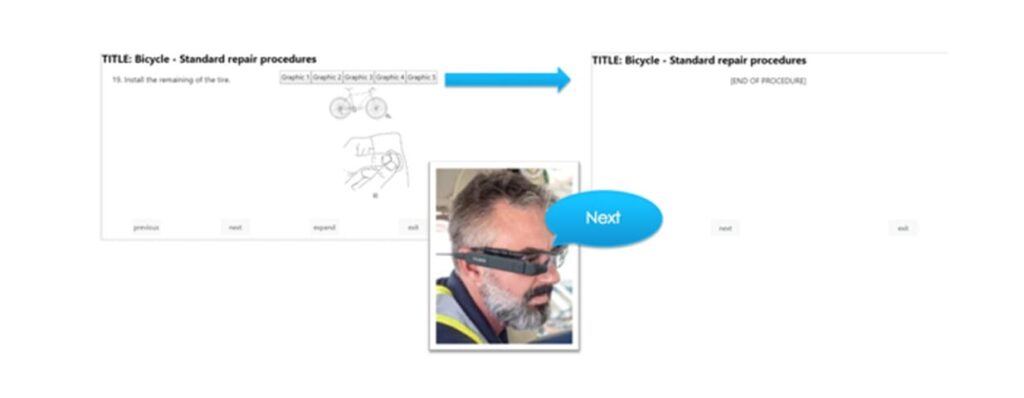

When all steps are complete, the AR Instruct software notifies the Service Engineer that the procedure is done and all steps are recorded as complete.

The Service Engineer exits back to the bar code scanner to begin a new work order or procedure.

It’s really that easy.

If you are looking to improve operational efficiency, appeal to the modern workforce, execute service checklists 3-5% faster and enable greater compliance and quality assurance over completed work instructions, AR Instruct is exactly what you need.

Want to see AR Instruct for yourself? Request a Demo today.

If your organization creates service information, work instructions, installation operator guides, user guides, technical instructions, service manuals, or even service procedure bulletins – it’s time to rethink your process.

Let’s talk about how to make your service information accurate, relevant and accessible.

Defects in products happen, but in the case that a product needs to be taken apart- it’s important to do it the right way. This is especially true with today’s advanced complex products.

This is why organizations often don’t question why they’re managing mountains of paper-based technical publications. But what happens when a service call involves the use of particular tools that aren’t quite outlined in a service procedure manual?

Or when field circumstances turn out to be different than the initial service order and the correct manual may not have made it into a technician’s vehicle?

What happens when technical publications designed to guide service are no longer relevant due to product or tool changes? Despite best efforts – service, installation, and operation problems arise. These problems cause worker confusion, dissatisfied customers, and business risk.

Providing information that no longer applies to specific products forces operators to troubleshoot challenges based on assumptions and experience – or worse – inexperience. Paper-based and locally stored procedures, instructions, and guidelines also have a tendency to make work instructions difficult to find.

If your procedure documentation guidelines are disconnected, they are only hurting you.

The good news is, with the help of simple technology, any organization has an opportunity to rethink their service information. There has never been a better time to make service information accurate, relevant, and easily accessible.

The solution? Interactive digital work instructions.

How to make service information accurate

You might be surprised, but as a matter of fact, the first step towards achieving accurate service information involves using the content (such as Tech Pubs, Arbortext, DITA, XML, Images, etc.) that your organization has already created. Evaluate the current service information processes your organization has in place. For instance, you might currently be using paper documentation.

What’s the problem with paper documentation?

Once your documents are committed to paper alone, you can no longer assure their ongoing accuracy. The underlying information could have changed right after it was printed! Your information should (most definitely) include the latest version of technical publications and content (such as Creo Illustrate, Windchill, Service Information Manager, InDesign, FrameMaker, Oxygen, etc.) that you already have without the need for added latency or work for authoring, styling, and publishing.

When you’re in a digital work instruction environment, that environment is set up to draw from the most accurate up-to-date information available on your system. This is why the best possible way to ensure the accuracy of your service information is to move away from paper workflows and go to digital work instructions – instantaneous access, up-to-date information.

How to make service information relevant

The best way to ensure that your service information is relevant is by connecting your technical publications back to your engineering and manufacturing content creators.

What do we mean by that?

Your work instructions, service manuals, operation guides, and bulletins all come from files you have on hand. So why shouldn’t they directly connect to and show operators and technicians accurate and relevant information about what they do?!

Furthermore, if your current service processes involve the need to find and locate product information before your technicians start the job, you end up losing valuable time.

It’s time to change that.

The way to make your service information more relevant is to have your instructions take your technicians down a specific product path. Using visual work instructions will allow your service teams to get specific information and insights that directly pertain to what they need.

By implementing technology that can cross-reference technical publication content, you can be sure your service information will always be relevant no matter the task.

The technology available today even has features like ‘work process selects’, to route directly to the correct tech pub content. Even better, it also has the ability to navigate to cross-referenced content such as DITA, XML files, images and more!

Simple solutions on the market today can even provide service technicians and operators with the ability to immediately start on a service task. With the help of technology, such as a digital device or a handsfree headset, service technicians can instantly receive relevant work instructions at their fingertips… or eyeballs… by simply scanning a barcode.

Your service information should be accurate and timely, and the best way to make that possible is by directly connecting all the files you currently have! It’s that simple.

How to make service information accessible

Making service information more accessible has everything to do with the use of digital devices such as mobile or wearable devices.

By using mobile or wearable devices, workers have the ability to instantly connect directly to work processes and even existing tech pub source content. Every organization has the ability to make service info easily accessible to the extent that the company wants.

For instance, you can easily make any information accessible and relevant now with a connected Industrial IoT environment. By using Wi-Fi and cellular connections, technicians have the ability to connect online to whatever the most relevant information is.

Your path to better service information

Please contact us to see how Industrial AR can be used to connect and reuse existing technical publications and content. We have the know-how, technology, and team to help you take your digital transformation to the next level, decrease service and manufacturing errors, and improve the way you distribute technical information.

Watch this video to see EAC’s solution for converting work instructions to digital AR experiences with AR Instruct.