If you’re wondering how the Form 3 compares to the Form 2, we’re able to tell you the differences between the two Formlabs 3D printing machines.

Types of 3D Printing

Stereolithography (SLA): a type of vat polymerization where liquid photopolymers resin cures under ultraviolet (UV) light; highly accurate and precise prints; builds 3D layers from the bottom up with support structures.

Digital Light Processing (DLP): the oldest type of 3D printing; a type of vat polymerization where liquid plastic resin cures under LED light; less quality/detail but faster print times than SLA printers.

Fused Deposition Modeling (FDM): most widely-used process; built layer by layer where the thermoplastic filament is heated to melt into a 3D object; slow 3D printing process, but can print large-scale.

Selective Laser Sintering (SLS): uses high-power lasers to fuse particles of powdered substances together; highly accurate and precise prints like SLA printing; builds light-weight prints with no support structures.

Selective Laser Melting (SLM): uses a high-powered laser beam to fuse and melt metallic powders together; used for complex geometries, thin-wall structures; popular uses in aerospace and medical industries.

Electron Beam Melting (EBM): main use is for metal 3D printing; uses powerful electron beam in a vacuum; uses powder bed fusion technique similar to SLM; used for strong, durable 3D prints.

Laminated Object Manufacturing (LOM): heat and pressure fuse plastic, paper, or metal – cut to shape with computer-controlled blade or laser; most affordable and fastest 3D printer used for large-scale rapid prototyping.

The newest type of 3D printing, created by Formlabs, is called:

Low Force Stereolithography (LFS): advanced SLA using a more flexible tank with lower force for even more accurate and precise prints; builds 3D layers from the bottom up with easily removable support structures.

Read more about LFS 3D printing in our blog, Formlabs Releases New 3D Printers using LFS Technology.

Form 2 SLA vs Form 3 LFS

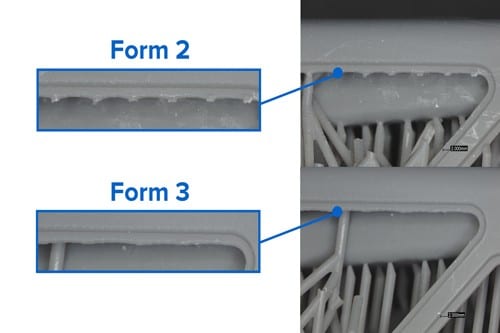

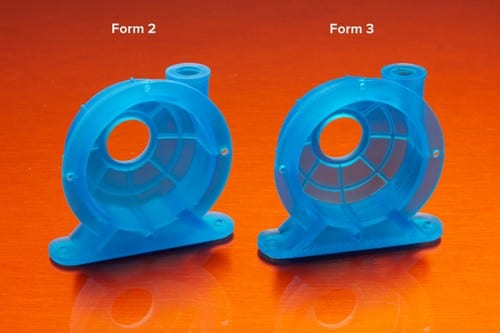

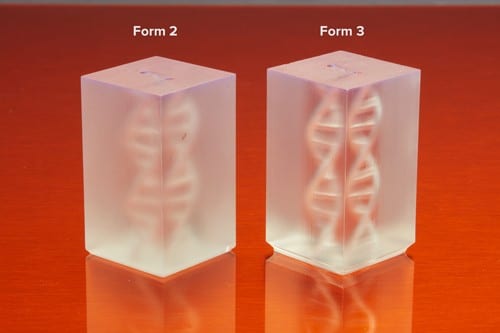

One of the benefits of printing with LFS technology is that the flexible tank significantly reduces stress on parts and prototypes during the peeling process. This results in much clearer parts with an improved surface finish as shown in the following comparison photos of a Form 2 and Form 3 print.

Lower forces with LFS also allows you to capture fine detail and smooth surfaces with minimal layer lines which results in improved quality prints and overall reliability.

Watch our step-by-step workflow 3D printing with the Form 3 to see Formlabs present on their newest technology!

Look back to my blog on the most frequently asked questions about the Form 2, Form 3 and the Form 3L. Please reach out if you have any questions and don’t forget to follow me on LinkedIn for more news in the additive manufacturing industry!