Formlabs is adding to their Tough and Durable family of engineering resins – they’ve released the Tough 1500 resin recently – and it’s the most resilient material they have.

You can use Tough 1500 resin on your Form 3+ SLA 3D printer.

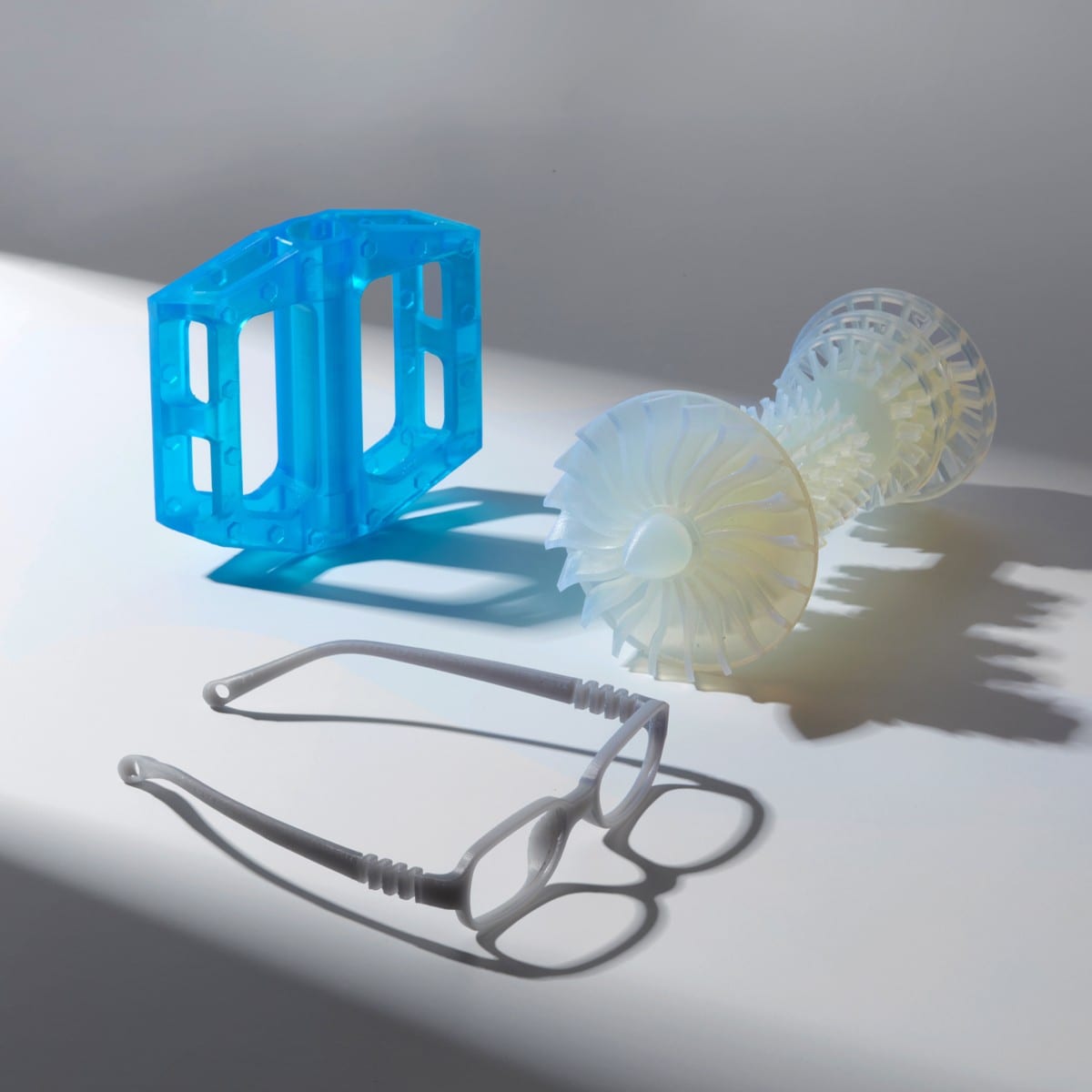

Tough 1500 Resin for Resilient Prototyping

Tough 1500 Resin is also the most robust, functional, and dynamic group of materials. Choose this resin for parts undergoing bending, tension, compression, or impacts that will bend or deform slightly before breaking. It produces stiff and pliable parts that bend and spring back quickly under cyclic loading.

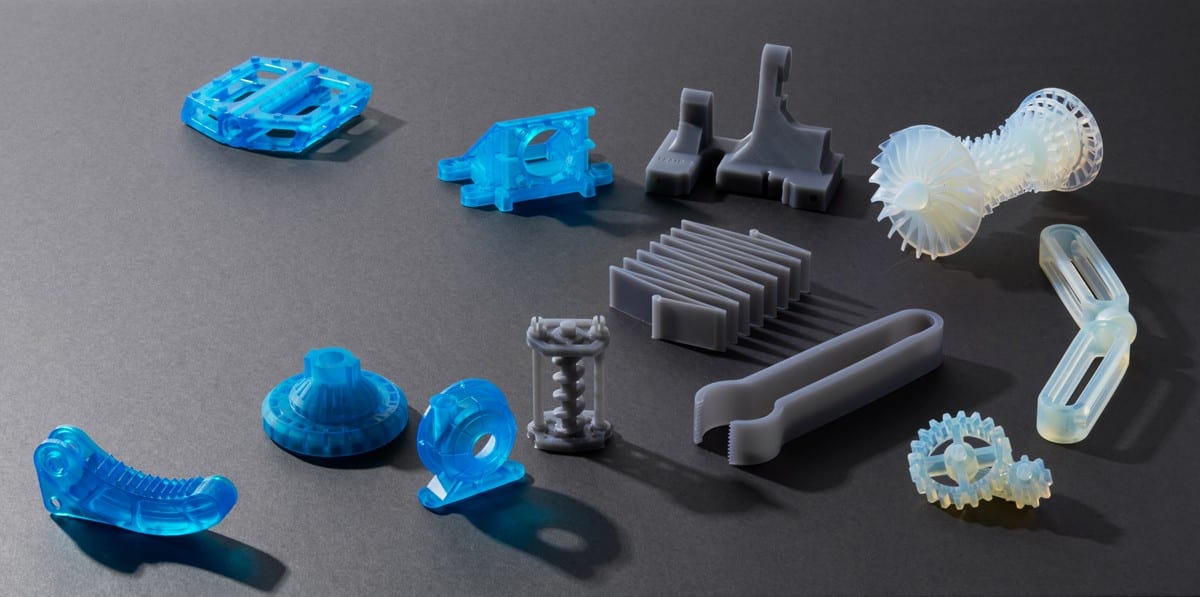

The family of Tough and Durable Resins share numerous characteristics and is great for functional prototypes, jigs and fixtures, connectors, and other shared applications. Identifying the best material for your specific use case involves understanding your design constraints and the key tradeoffs between the materials.

Tough 1500 Resin is ideal for:

- Prototypes that repeatedly bend and quickly return to shape

- Jigs and fixtures requiring repeated deflection

- Simulating the strength and stiffness of polypropylene (PP)

Due to its high elongation and moderate modulus Tough 1500 Resin is ideal for parts that bend, but require high memory retention. When pushed to its stress limit, Tough 1500 parts will strain significantly before permanently deforming and ultimately breaking.

Download the Tough 1500 resin data sheet to get more details on material specifications and tech stats.

Why was there a need for another tough 3D printing resin?

“Unfortunately Tough is WAY too brittle in a lot of applications!”

“I see a bit of a sag with Durable after the print finishes.”

These are direct quotes from one of Formlabs customers when using the only existing engineering resins at the time. Formlabs understood there was a gap in the Engineering family and decided to add the Tough 1500 resin to stay competitive in the market and to increase their value proposition to customers.

Customer Testimonial for Tough 1500 Resin – Unplugged Performance

Unplugged Performance is the world leader in premium performance upgrades for Tesla vehicles. Some of these upgrades involve installing customized car bumpers.

Before 3D printing, it would take Unplugged Performance roughly 45 minutes to remove each sensor mount from the existing bumper and another 10 minutes to bond it onto the new bumper. At six sensors per car, in addition to other custom upgrades, they were only able to complete one car every one-and-a-half days.

With their Formlabs printer, Unplugged Performance now prints new sensor mounts in batches of 30. This eliminates the costly time spent removing the sensor mounts from the existing bumper and leaves them with only the bonding step of their workflow. This helped improve their throughput to three cars per day.

Unplugged Performance uses Tough 1500 Resin for the printed mounts due to its compliant nature, which enables it to clip onto and secure the various sensors. Tough 1500 Resin’s high impact strength enables safe mounting of the sensors in the car’s bumper as well.

Unplugged Performance also prefers the grey color of Tough 1500 Resin compared to Tough Resin and Durable Resin. This has opened up new opportunities to create visible custom parts that blend seamlessly into the car’s interior.

How to order Tough 1500 Resin

Check out our Formlabs Resin Library where you can order a free sample part or order the resin if you’ve already decided it will work for your application. Watch this video of our Additive Manufacturing Specialist with a part made from Tough 1500 – which would be the exact part you’d receive if you order the free sample.

Follow Lauren on LinkedIn for more Formlabs tips and tricks.