In our new ‘3D Printing Show’ episode Anthony Bayerl, Director of Marketing, and Lauren Adey, Additive Manufacturing Specialist bring you the latest news in the 3D printing industry.

We talk about new product announcements, tips and tricks, product updates, discounts, and promotions.

Watch our video to learn about the latest additive manufacturing news.

The Future of Metal 3D Printing

Metal 3D printing will pave the way for the future by providing advancements in mass production of 3D printed products such as heat sinks, spare parts, structural components, tooling, medical devices, and industrial automation.

Leading companies like HP are at the forefront of this technology, producing large-scale metal 3D printers that use materials like gold, copper, steel, and titanium to build custom, complex parts.

HP’s article called, Future of Industrial Production: The Metal 3D Printer, points out that we can most likely expect metal 3D printing companies to offer services to print parts and prototypes for other companies in the near future.

Form 2 Finish Kit

The Finish Kit for the Form 2 helps you stay organized while putting finishing touches on your parts and prototypes.

The Finish Kit includes:

- rinse station

- 2 rinse buckets

- rinse basket

- rinse bottle

- finishing tray

- tweezers

- scraper

- removal tool

- jig

- flush cutters

- disposable nitrile gloves

Removing parts after leaving the Form 2 to finish the 3D print overnight

We discuss how Jeff Martin, an Application Engineer from Colder Products (CPC), gives us a tip on how to remove 3D prints from the build platform even when it’s been finished for hours and sitting in the 3D printer.

When you’re printing with material like the rigid resin, it can be difficult to remove if the resin is no longer warm from the finish. Martin suggests using scolding hot water on the surface of the build platform to help scrape off the finished 3D part.

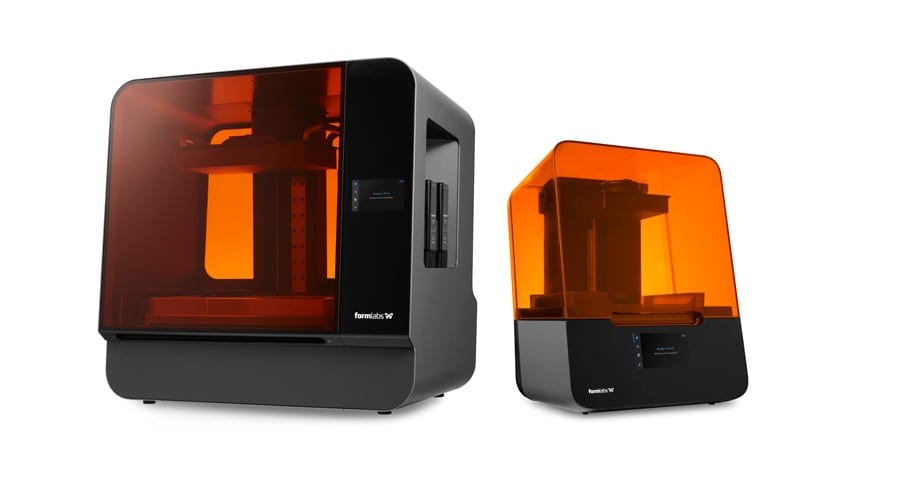

Formlabs Stereolithography 3D Printers: Form 3 and Form 3L

The Form 3 and the Form 3L from Formlabs are here! These 3D printers use a process called low force stereolithography (LFS) for optimum printing details. Read more about the new LFS process in our blog called, Formlabs Releases New 3D Printers using LFS Technology.

Multiple 3D Printers In-House

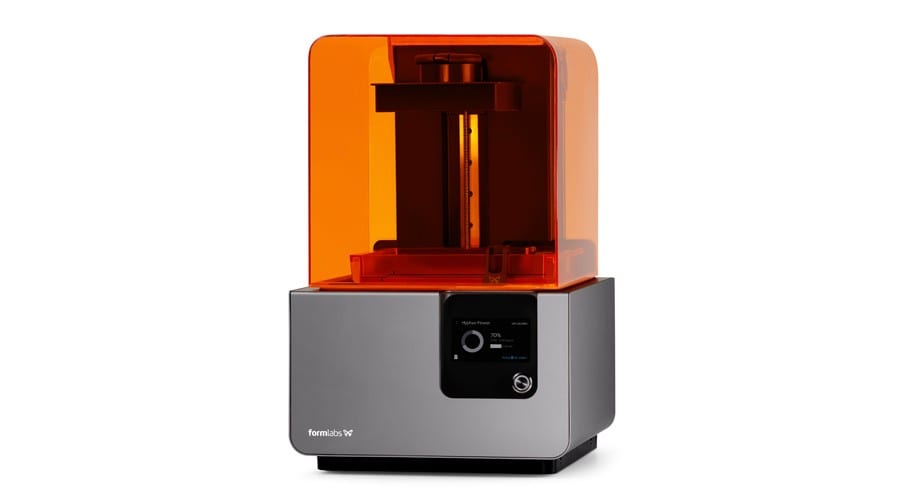

In our last post, we mentioned that the Form 2 desktop SLA 3D printer has decreased in price (from its previous price of $3499) to $2850.

If you have always had a print queue, now is the perfect time to buy another 3D printer to use in-house for your parts and prototypes. Now you can excel in rapid prototyping with multiple 3D printers at a low cost.

Read our blog called, 3 Ways 3D Printing In-House Can Transform Your Design Process, to learn how you can benefit from having more than one 3D printer.

Contact Lauren Adey, our Additive Manufacturing Specialist, to take advantage of these special deals! And make sure to follow her on LinkedIn to see more on the latest 3D printing news.