Our world is rapidly becoming a place where big data reigns supreme. Just like a king!

Product lifecycle management is an all-encompassing technology solution for integrating and managing all types of data inherent in the design, development, production, support, maintenance and final disposal of manufactured goods and product offerings.

The ultimate goal of product lifecycle management is to accelerate the entire cycle of product development and improve business efficiency and profitability. In its most basic sense, PLM software is a collaboration tool that facilitates organizations to manage their product information across a wide spectrum of internal and external business processes and functions.

PLM is an integrated system that facilitates the collection, sharing and management of crucial data – a broad-based approach that governs the development of a product right from the idea conception to the ultimate disposal.

One System for Everything: Product Lifecycle Management

The product lifecycle management is a business process management tool that serves as a repository for every teeny little bit of information that might affect a product offering. It is essentially the first place where all product information comes together from different stages of production – be it supply chain, production, procurement or marketing. By consolidating diverse systems in an organization, PLM helps create a coherent data structure to develop, manufacture and retire products.

One of the most compelling benefits of the product lifecycle management approach is to empower businesses to make smart, timely and information-driven decisions at each stage in the overall product lifecycle. Of course, your product development process is unique to your company and a one-fits-all PLM approach might not work for you.

However, like most businesses, your company also depends on the quality of data that is available to make critical decisions on a day-to-day basis. PLM offers a unified, collective intelligence that helps improve the strategic decision-making process, define processes and workflows, eliminate process bottlenecks and accelerate the overall product development process.

Get the benefits that PLM has promised for years

The cradle-to-grave approach of product lifecycle management offers many benefits for companies seeking more efficient, profitable product development, and management solutions.

In the present scenario, PLM has emerged as a single vital source for managing the different aspects of product management throughout the production, development and retirement processes.

It is no secret that faster product development and shorter lead times to market have become the key to marketplace competitiveness and success. With PLM solutions, the product can be developed and finished faster. As a powerful enabling technology platform, PLM applications help integrate people, processes, business systems, and of course data to streamline the product information spinal column for your company.

The innovative technology of PLM enables your business to reduce production and material costs through prototyping, waste reduction and savings through the full integration of engineering processes and workflows. This naturally leads to enhance production efficiency and increased productivity. The robust data analytics tools, such as visual analytics of a PLM application simplify the overall processes, workflows, communications and information flows throughout the production cycle.

It leverages the full potential of integrated business systems and functions across the company, from supply chain to production and from compliance to financial divisions. Product life cycle management solutions ensure more transparency in policy disclosure and the organizational decision-making process.

Acting as a line of a message between owners, managers, suppliers, employees and customers, PLM aids open communication and conversation amongst the various stakeholders. This helps you identify and understand what works and what does not work for your company.

What to look for when purchasing PLM software

When people purchase PLM systems, they essentially invest in technology which provides a wealth of ease and convenience given that the systems are extremely complicated. This is a core reason users often find it difficult to navigate these systems, let alone make full use of all the features it offers them.

When selecting a particular PLM solution for your business, it is important to ensure that it is easy to use, navigate and apply in the various stages of the production cycle.

Another feature to consider is the ability of the PLM software to integrate with and complement readily with the systems and processes already in place at your organization.

The PLM application that you procure from a vendor must come with certain features such as BOM (Bill of Materials) management, reporting and analytics, quality management, change management and product data management.

While these elements help in the overall coordination, tracking, control and management of the various workflows involved in the production, the best PLM software should also offer functionally enabling deeper supplier collaboration, flexibility and accessibility, speed of implementation, environmental compliance and support for existing organizational systems.

PLM Applications for any PLM system

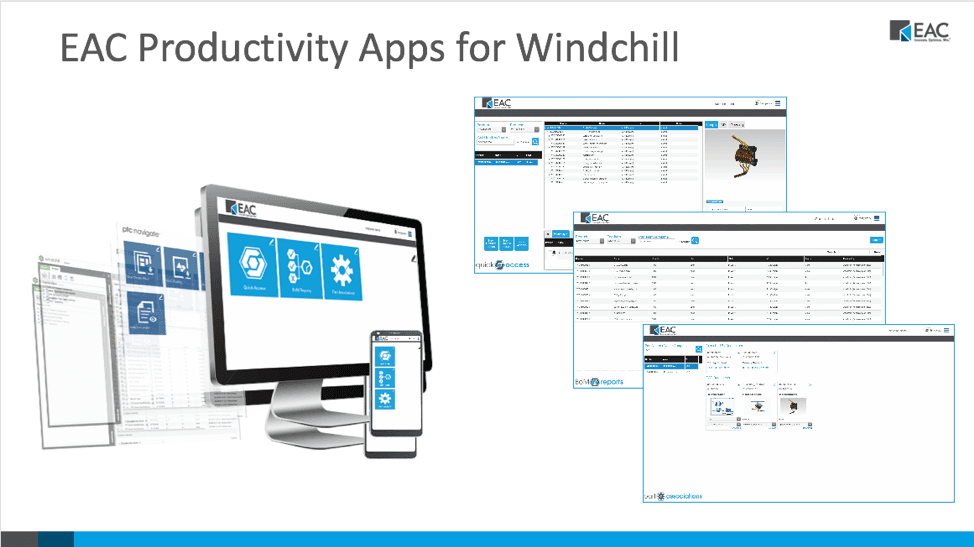

So what are we suggesting? Our solution to an easier way for everyone in your organization (not expert PLM users) to use Windchill and find product data is our EAC Productivity Apps. You can learn more about our EAC Apps on our website.

EAC Product Development Solutions introduces the powerful EAC productivity applications that make it easier for you to view, understand and manage product data.

With one single, simple and powerful interface, you can make better, faster and more effective decisions at your company. Our PLM system applications are compatible with product lifecycle management systems, thereby offering an integrated technology platform for multiple enterprise systems including ALM, MRP, ERP, SLM, CRM, Accounting, and PLM (Windchill). The cookie-cutter PLM solutions by most vendors tend to be overly complicated which inhibit your ability to consolidate task workflows and streamline production processes within your organization.

Our PLM apps work as a connectivity tool, to transform the entire PLM experience. They facilitate user experiences by allowing them to perform functions without prior training, making the PLM interface easy to work with. EAC Productivity Applications provide an added advantage of connecting with a PLM system and altering the user interface, making PLM easy to understand. They have the capability to pool data from many enterprise systems and put it on one screen.

Our goal is to give power to the manufacturers.

We have successfully eliminated the common PLM system bottlenecks and complications by coming up with our own PLM solutions that reduce the bare bones you might experience in run-of-the-mill PLM software and applications available in the market. Our PLM applications were developed to offer you a perfect user experience by improving accessibility to critical data.

With our top of the line PLM apps, everyone can use the system with relative ease and businesses can fully tap into the large PLM investment they were initially promised.

Fill out this short form to watch

this educational video on our EAC Apps:

Or if you'd like to talk to someone directly about our EAC Apps, fill out this form and an EAC representative will call you as soon as possible. OR call us at 1-888-225-7579.

Why is it important to manage your product Bill of Materials (BoM) in a PLM (Product Lifecycle Management)? This is a tough question to answer across the board for every company, but this article breaks down what you need to know.

The level of BoM management in PLM can be dependent on your companies’ products, downstream systems, and product development processes.

With that in mind, here are some general benefits and reasons to manage the creation of your product BoM in PLM.

The benefit of bill of materials management in PLM

PLM in nature is meant to be a tool to help engineering manage their production date while allowing dynamic collaboration and change control throughout the product development cycle.

The data managed in a product lifecycle management system includes CAD and BoM information, as well as additional supporting product information and documentation.

PLM functionality typically allows an organization to store any and all product information in a structured manner. The structured manner is what properly represents the product within all stages of the product’s development.

This includes everything from initial design requirements, to manufacturing requirements and process plans, to quality assurance documents- all linked to a single product structure.

This gives you the ability to graphically see a truly complete representation of any and all products managed within the PLM system.

In addition, many of the top PLM systems (such as PTC Windchill) give you the ability to manage different views of a single bill of material.

For instance, you could see the design or engineering view of the structure and all design information needed for that BoM product structure.

You would also have the ability to look at a manufacturing view that has the structure defined in a way to support the best possible manufacturing process, while it also links to any supporting information and work instructions.

Additionally, you could see a service BoM that represents exactly what is on-site or on the hands of a customer, with linked product information specifically related to service or support (such as a service repair or product manual).

These systems focus on tracking and managing all cost and profit throughout the process.

Because of this, changes are tightly controlled and require significant steps to ensure proper applications across the system.

There are also few systems that allow for full product representation inside of ERP or MES as outlined above. Nor do they fully support many different views of the same BoM.

ERP tends to only manage what is required to properly manufacture or sell a product, which does not always represent the full product design or its full breadth of supporting information and documentation.

There many impacts on these fundamental differences.

When to use PLM for BoM Management

Here are some general concepts as to when to use PLM for BoM management.

When your product development is in the dynamic phases that require many changes and updates at each phase gate, your bill of materials should be primarily managed in PLM.

If your product requires specific requirements management, detailed manufacturing, quality work instructions, or an intensive manufacturing process, it’s in your best interest to use product lifecycle management for your BoM.

At the very least, all of your product information should also be managed, or linked to your product lifecycle management system to ensure full accountability to all information updates required in the instance of change.

Integrating ERP and PLM

At a minimum, if you have an ERP system it’s important to integrate your system together with PLM.

It’s essential to establish key integration points between your enterprise systems that send needed information back and forth to your enterprise resource planning solution. This will help you properly execute new product releases and changes.

By integrating your systems, your ERP processes will ensure all proper tasks and functions are executed in your ERP or MES systems.

From there, your ERP to PLM system integration would send information back to your PLM system to close the loop.

These are our best practices to help you get ahead and to take product data further. We would love to hear about your thoughts about this topic and answer any additional questions you might have. Feel free to drop a comment below or leave an inquiry under let’s talk.

Looking for an easy way to quickly assess your bill of materials and ensure projects stay on-time and on-track?

Here’s why every manufacturing company should be considering product lifecycle management applications.

Expand PLM software usage throughout your enterprise with PLM apps

Let’s face it, no company uses a single product data management system (PDM) or a Product Lifecycle Management (PLM) system for ALL of its organization’s needs.

Your organization likely uses an abundance of different technology software to collect and store data. These technologies can include customer relationship management (CRM) systems, quality management system (QMS) software, enterprise relationship planning (ERP) systems, application lifecycle management (ALM) systems, and so many more.

If your organization currently uses a PLM system, odds are you most likely paid a pretty penny for it. So why not make the most of that product lifecycle system investment and use your system’s complete functionality?!

Product lifecycle applications support, enable, and enhance the value and footprint of PLM software. PLM Apps go a long away to assist and ensure consistent access to up-to-date product data. They can help expand controlled access to valuable content and give functional groups a single simplified view of files, data, and content all within a single browser-accessible screen.

You’re going to want to invest in these kinds of advanced technology solutions that simplify data gathering processes and expand the value of your PLM investment. PLM apps are meant to help you find data easier which reduces user frustration and helps take productivity to new levels within your organization.

PLM applications, also referred to as PLM system plugins, deliver on the dreams of many organizations. They are a simple solution that drastically increases enterprise PLM usage.

PLM apps integrate siloed data from disparate systems

With the use of multiple complex enterprise systems, your organization’s data is most likely held captive in siloed systems. Many PLM applications help connect these disjointed enterprise systems using common application programming interface (API) connection abilities.

PLM apps simply pull data from other enterprise systems into a new user-interface through API integrations. They don’t rely on interface features from other enterprise platforms or systems (besides the data and information they extract), therefore, they are less likely to be affected by a new release of the underlying enterprise systems!

PLM apps simplify searches for the occasional PLM software user

PLM apps change the user interface (UI) and user experience (UX) of your PLM system so that it’s easier to use. This can be useful for occasional or novice users who can feel overwhelmed by the complexity of their PLM system compared to those that use their PLM system on a daily basis.

PLM applications offer user-friendly interfaces that simplify the complexity of PLM systems and make it easier to search, find, locate, and understand product information. In fact, many of these tools even allow organizations to adjust settings for specific users (such as purchasing, marketing, accounting, etc.) so they can access the direct information they need.

PLM apps Many customers we work with use complex product lifecycle management systems such as PTC Windchill or Siemens Teamcenter. Due to the robust capabilities of these enterprise systems (and other PLM systems), many users find product data hard to navigate – especially if they aren’t daily users within these systems.

PLM apps speed up product development processes by providing users with complete access to real-time complex enterprise data.

Product lifecycle applications really do make PLM easier – see it for yourself by watching this short PLM applications video.

Customize PLM apps without disrupting your PLM software

PLM applications and system plugins offer simple and easy ways to customize enterprise product data systems. A PLM Administrator can customize the apps to conform to their company’s goals and prioritization of tasks without disrupting the PLM software itself.

Time after time, we see organizations add PLM customizations to their mainframe PLM software, only to wind up facing dozens of challenges as new system software versions get released. Because PLM apps are an extension of PLM software systems, they are minimally affected by upgraded software versions and updates (if at all).

PLM apps provide organizations with the ability to easily custom tailor simplified product lifecycle management interfaces or mashups. This functionality provides additional value and integration capabilities with other enterprise systems.

PLM Applications offer a brand-new UI for your intricate product data management system; enabling a fresh and simple user experience. They also have started to help organizations solve problems easier and faster with direct, accessible, and instantaneous insights from data.

Your systems are only as good as how you use them. If employees struggle to navigate your product lifecycle system interface, PLM apps are definitely something you should be looking into!

How PLM apps drive flexibility within your organization

PLM applications provide access to PLM information to employees outside of engineering such as marketing, sales, finances, and procurement.

Access to PLM system data provides another way for teams to identify the broad scale of their day to day activities and information. This can help teams understand and prioritize tasks to be more efficient and productive.

This flexibility allows teams to work the way they want. By enhancing a complex system and tailoring each end-user experience, it’s easy to see how these PLM system plug-ins can drastically improve productivity and drive value across an organization.

What is better than providing every department with product information that they want and need to do their job?!

Want to learn more about PLM Applications and how they could pair up with your current enterprise systems? Let’s have the conversation!

You’re likely to have experience with Bill of Materials (BoMs) if the nature of your business has anything to do with product development.

Let’s talk about why bill of materials are so important, how BoMs impact business, and the best BoM management practices. Or check out another helpful article on BoM management, “How BoM Management plays a role in your PLM processes“.

The importance of bill of materials

BoMs define products as they are designed (CAD or engineering bill of materials), as they are ordered (sales bill of materials), as they are built (manufacturing bill of materials), and as they are maintained (service bill of materials).

They incorporate product information from design and engineering, document control, operations, manufacturing, purchasing, contract manufacturers, and more. Bill of materials influence inventory levels, material purchases, shop floor assemblies, and so much more.

In fact, departments often rely on BOM records to get the job done right. Whether you realize it or not, your BoMs drive and affect your businesses’ operational success. This is why it is so important that your organization creates and manages well-organized, correct and up-to-date bill of materials.

BoM information accuracy and why it matters

BoMs require complete and accurate information, in order to successfully benefit design, manufacturing, sales and service building quality products.

The accuracy of BOMs influences an organization’s ability to make well-rounded product development decisions. These decisions fundamentally impact the efforts organizations peruse to generate a product in the most efficient, cost-effective way.

Oftentimes creating BOMs requires input from design, procurement, manufacturing, and sales. Using manual methods to collect and enter items on various BoMs increases the risk of producing inaccurate, out-of-date, or even possibly duplicate BoM versions.

Furthermore, if departments produce products based on incorrect or inaccurate bills of materials, delays to market can occur. This can not only be very costly for an organization, but it oftentimes impacts an entire supply chain.

Inaccurate bills of materials are one of the costliest errors engineering companies can make. In order to avoid the risks of inaccurate BoMs, many organizations have started to reevaluate the way they create, manage, and share product information.

BoM management processes

Bills of materials (such as eBoMs, sBOMs, mBoMs) are most-likely part of your product development process. That being said, what are your current processes for managing those BoMs?

How do you share, collaborate, and ensure the accuracy of your organizations’ bills of materials? Do you find it difficult to manage the differences between them and keep the data consistent across eBOM (engineering bill of materials) and mBoMs (manufacturing bill of materials)?

Odds are if you have yet to implement technology solutions to manage your bills of materials, your methods for BoM management most likely involve spreadsheets, emails, rekeying information, and multiple other systems of communication.

If this is the case, don’t worry – you’re not alone. Studies show nearly 50% of product development companies still use spreadsheets (or sometimes even nothing at all) to manage complex bill of materials!

Despite the big workload that BoM management represents, many organizations are still comparing bills of materials in excel spreadsheets or by opening separate BoMs and manually connecting the dots. This management approach is not only tiring, but it also increases risks of human error and mistakes, especially if the bills of materials are very long.

In fact, is not unusual to find one giant excel spreadsheet on top of information managed by PLM (product lifecycle management), ERP (enterprise resource planning), CRM (customer relationship management) and other databases. Why is that? The information required to assemble bill of material documents tends to reside within separate, disconnected enterprise systems.

It’s time to change that.

Connecting business systems and information

In a world of complex, role and department-specific enterprise systems, productivity can seem quite limited. But the truth is, with the help of technology, businesses no longer need to operate this way. Collaborative solutions exist, and they really are as simple to implement as they, well… should be.

System integration tools (such as applications) change the way organizations create, manage, and share product information- without even having to upgrade or change current enterprise systems.

Using system API connections, applications can pull data from disconnected enterprise systems and consolidate it into centralized dashboard display windows. In fact, many integration applications are even ready to go straight out-of-the-box (yes, this means they require absolutely no special configurations or complicated implementation at all).

For instance, productivity apps offer simple, role-based access to data and other enterprise systems making it easier for stakeholders to view and understand consolidated product information and data. What makes simple applications that integrate enterprise data even better is the fact that most of these system collaboration tools are even affordable.

With a single view to into multiple enterprise systems (such as ALM, MRP, ERP, SLM, CRM, Accounting, and PLM) you can be sure that users have access to the latest and most accurate product information when they need it, and how they need it. There’s really no catch. Productivity apps really are solutions that are; easy, affordable, and that solve the complexity of dealing with multiple disconnected enterprise systems.

Effective BoM management & bill of materials software

Parallel to system integration apps that can pull and consolidate enterprise data, BoM applications can also automatically consolidate real-time data across enterprise systems.

This means organizations can enable real-time BoM collaboration – and that is a game changer.

Real-time BoM collaboration empowers users with capabilities to collaborate and work together creating a bill, sharing BoMs and associated data, and even preview CAD drawings and images. It also opens up the ability to simultaneously edit manufacturing bill of materials, while completely avoiding duplicate and inaccurate documents. This enables users to get a virtual ‘live view’ of data.

Users are able to maintain and manage all associated product documentation such as part datasheets, materials required, CAD drawings and files, as well as anything else that is needed to manufacture a product all in one centralized location. This reassures one sole accurate and revision-controlled bill of material for a product.

This is exactly why it is so important to establish systems and methods that enable all departments within your product development process to be able to share, collaborate, and ensure the accuracy of your bills of materials.

A simple bill of materials software

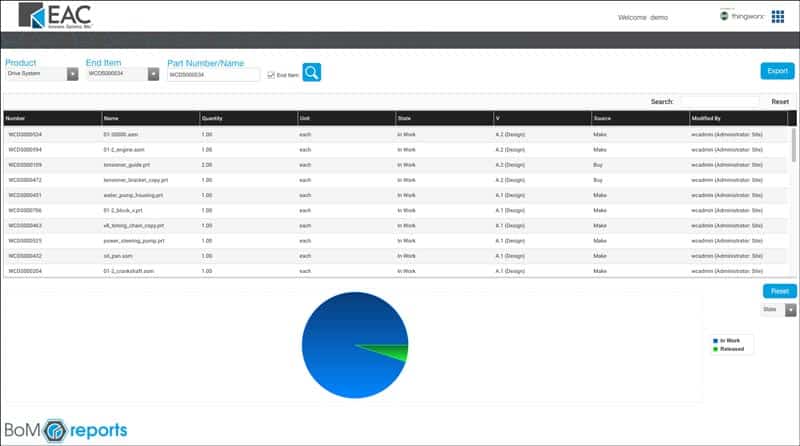

Our experts at EAC Product Development Solutions recognized the need for better BoM management within many organizations- That’s why we created our bill of materials software application, BoM Reports.

Our BoM Reports PLM application is essentially an out-of-the-box PLM system plugin. It’s easy to use, simple to integrate, and an extremely affordable for any organization.

We designed our Bill of Materials Reports application with the intention of making manufacturing bill of materials and engineering bill of materials management ‘easy’ for organizations of all sizes. Meaning- our bill of materials software can even work for small businesses!

Our BoM Reports app delivers access to your accurate bill of materials database while it provides visual representations, cost rollup for materials, and detailed informational listings of items within bill of materials.

We guarantee our BoM Reports application will enhance your bill of materials management. In fact, it has changed the way many of our customers do business.

Our EAC Productivity app enables purchasers to see product cost roll-ups during design, so they can hit cost targets. It allows project managers to see the highest level status and availability of constituent parts so they can keep projects on time and budget. It helps fabricators see what version of parts go into the build so they can prevent scrap and rework- and SO much more!

We’re excited about how our organization is enhancing product development and we would love to share more information with you about how our EAC productivity apps really work.

If you would like more information about apps that could work for your business insert your information below. We promise not to fill up your inbox with overloads of information, we simply want to share tips, tricks, and tools that will help your organization succeed.

These days product data is everywhere. Everyone seems to collect it, have a lot of it, but the question remains; how exactly can you ensure your organization’s product data is being put to good use?

It’s time to take your product development one step further by providing role-based data access, connecting your enterprise systems, and learning how to make the most of your product data. I am going to explain exactly how easy that is to do.

The current state of product data

Companies today have many different roles that require access to product data. This may include people outside of the typical roles of which you may be thinking.

Departments such as engineering, manufacturing, that’s a given, but expand your thinking to include operations, purchasing, and marketing. They all need data access in order to edit and consume information. Think about sourcing…I’ll stop there, but you get the idea.

Let’s focus on the engineering department for a moment.

People could be involved from the mechanical side, the electrical side, or even a quality standpoint. Beyond that, people need to either contribute or consume information that could include manufacturing, service, sales, and more.

Product data game-changers

Product data silos limit productivity – PTC & EAC have the answer.

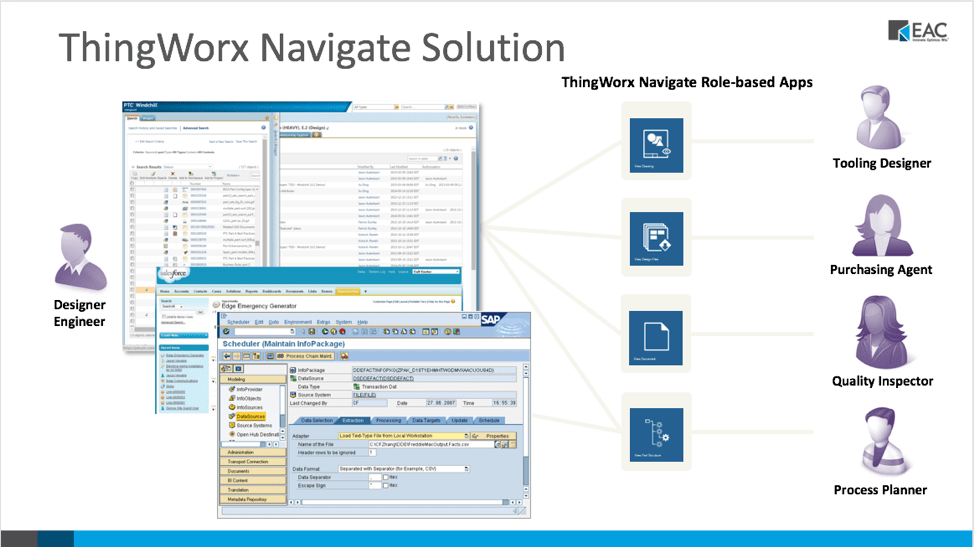

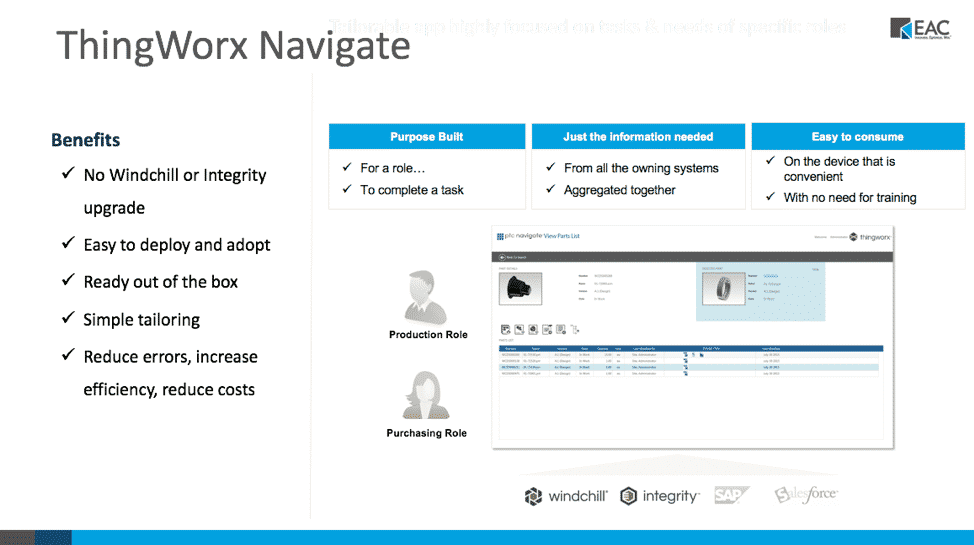

PTC ThingWorx Navigate was designed to address data accessibility problems by providing simple role-based apps that deliver just the right information to different groups (or departments) in the way that they need

When non-engineering colleagues need access to vital information, they typically interrupt an engineer or designer with a request. ThingWorx Navigate eliminates that distraction and “double-billing.” Through role or task-based self-service applications, data can be securely shared with a team. That way non-expert teams can use a simplified user interface to access the product data they need, right when they need it.

To help accelerate product development processes and take product data even further, our company (EAC Product Development Solutions) has also created what we call EAC Productivity Apps that work alongside ThingWorx Navigate apps.

So what’s the difference between ThingWorx, ThingWorx Navigate and our EAC Productivity apps?

This is a great question- I am going to try and paint the picture for you.

First, it’s important that you understand what ThingWorx is and how it is different from ThingWorx Navigate.

ThingWorx is the proper name of PTC’s Internet of Things (IoT) platform comprised of 5 components; foundation, industrial connectivity, analytics, studio,

The foundation component is the heart of the ThingWorx loT platform used to make connections to ‘things’ which could be machines, products or software systems or pretty much anything with an IP address and a communications interface.

User interfaces to the data coming from these connections are displayed on websites called ‘mashups,’ created with ThingWorx foundation. You might know these perhaps as ‘data mashups’ or possibly as ‘data dashboards’. Simply put, Thingworx is the IoT platform that makes everything possible. (Here’s exactly what makes Thingworx the leading technology for industrial IoT)

Then you have ThingWorx Navigate.

ThingWorx Navigate is the proper name of PTC’s applications that

ThingWorx Navigate Apps use a Windchill (PLM) connector to extract product data for presentation to Windchill Product Lifecycle Management users.

Fundamentally, ThingWorx Navigate Apps are all simply data and product information mashups created with ThingWorx. With ThingWorx Navigate you receive out-of-the-box apps that are instantly ready to be used with your PLM system. The idea behind these product lifecycle management apps is to ensure users can capture the complete functionality of their PLM (product lifecycle management) investment.

ThingWorx Navigate PLM Apps include:

View Design Files – A design file would be a format of a file that isn’t the native CAD format. This could be a staph or Induce or perhaps a 3D PDF

View Drawing – Allows you to look at just drawings. This application pulls drawings from your Windchill PLM system.

View Part Properties – This feature allows you to look at part properties- as if you were hitting the ‘Information button’ next to a file.

View Parts List – Allows you to look at bills of Materials (BOMs)

View Part Structure– With the View Part Structure App, ThingWorx is actually going into PDMLink and showing different aspects of a specific part instead of different ways of going at it (such as having to open several different tabs to get information). Using this application, you can get all your information together on one page. This feature also includes capabilities that cross-highlight part structures within your product. For instance, you could select a component and it would highlight that part and create a hyperlink that allows you to directly look at that specific part. This feature essentially creates a mash-up that takes information from different places inside of Windchill PDMLink and brings them together putting them on one screen, allowing you to have all your information at your fingertips.

View Document & View Document Structure

If you would like to learn more about ThingWorx Navigate technology or if you have any questions, you can always request to talk with Thingworx Navigate specialists here.

PLM Applications created by EAC

Our EAC Productivity Apps (also known as product lifecycle applications)

They allow departments to access content and perform common tasks through a very simple interface, versus having to use a complex product lifecycle management system (PLM) or Enterprise Resource Planning (ERP) system.

PTC Navigate Apps vs. EAC Productivity Apps

Our EAC Productivity Apps provide capabilities beyond that of the out of the box ThingWorx Navigate apps.

In short, ThingWorx Navigate applications allow you to securely access and present role-specific data from your Windchill system. They provide all of the power of a Product Lifecycle Management (PLM) system to someone who is not familiar with its ins-and-outs of product data management.

EAC Productivity Apps take it a step further by taking the underlying technology of ThingWorx Navigate, and the ability to get at the information in the PLM system and create even more complete applications that really give individuals instantaneous access to the information and product data they need to do their job. EAC’s PLM applications are created using PTC’s ThingWorx IoT platform, however, they can run independently of ThingWorx Navigate.

These apps are unique to EAC.

While built using the same ThingWorx foundation, ADK and [Windchill connector], they have their own look, feel and functionality. These mashups are packaged and sold together as a collection. EAC Productivity Apps created for Windchill promote user adoption and amplify the return on the investment you’ve made in your Windchill system, as well as extending role-based visibility into relevant product data and the impact PLM has on your organization.

Take your product data further with EAC Productivity Apps

Every subscription of EAC Productivity Apps includes free access to EAC Productivity Home. EAC Productivity Home is a proprietary framework, or launcher, for ThingWorx Navigate applications.

It sits on top of Windchill and

The EAC Productivity App, Quick Search, provides a simple way for users to find content in Windchill. It removes the need for users to apply an understanding of how Windchill objects are related in order to find the information needed to do their job.

The Quick Search PLM application also allows users to search for components and retrieve information and file formats. For instance, if you were to grab a drive system and do a quick search, it’s going to find product information such as parts, EMP like documents, CAD files and more. See EAC Productivity Application Quick Search in action here.

You can also learn more about the Quick Search features in this brochure.

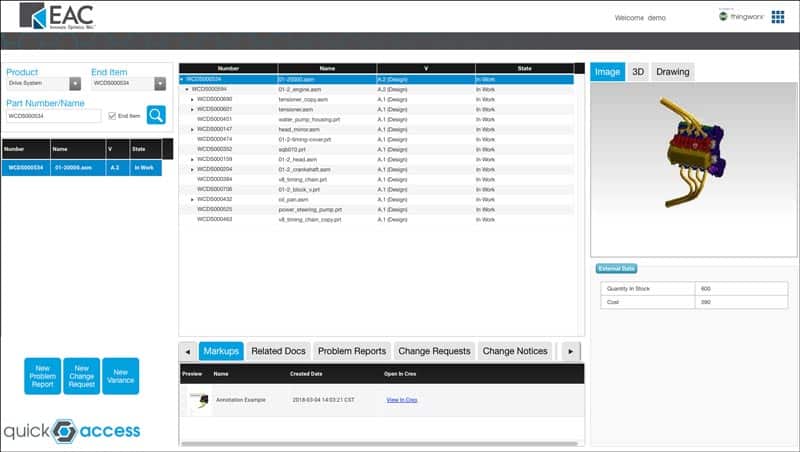

The Quick Access EAC Productivity Application streamlines access to critical and select data sets. Simplifies downstream users feeding critical quality information back to engineering with minimal effort.

This EAC Productivity App allows downstream users to feed critical quality information back to engineering with minimal effort. The simplified interface and consolidated task workflows help users easily submit new problem reports, new change requests, and new variances.

For instance, you could select a component (such as a product), pick its name (the end item number), search for it, and you would get straight to assemblies. With the use of Quick Access users can easily submit new problem reports, change requests, variances and more.

You can learn more about Quick Access features in this brochure.

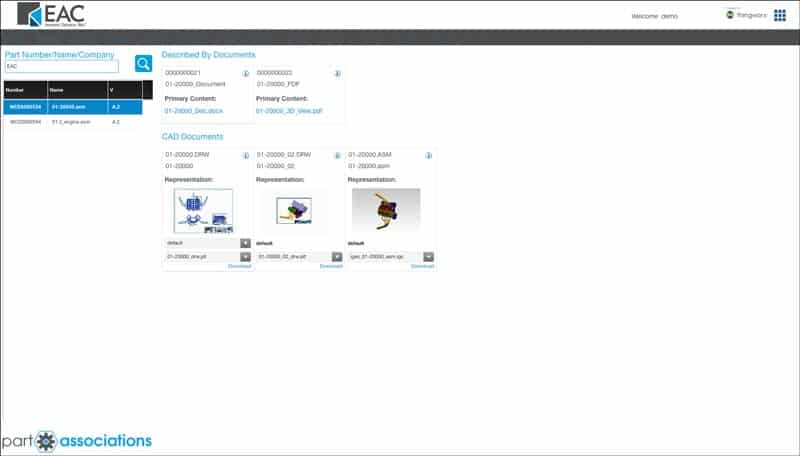

The Part Associations EAC application provides a “shortcut” for non-CAD users to access critical files and documentation associated with designs like drawings, parts, assemblies, and other documents associated with CAD files and part data.

You can learn more about Part Association features in this brochure.

BoM Reports App provides a visual representation of cost

This EAC Productivity App allows users to quickly assess a Bill of Material and ensure projects stay on-time and on-track. The simplified view helps ensure products are built with the appropriate design iterations. With the use of BoM Reports users can easily see BoMs, lists of unreleased parts, parts that have been created or modified by specific users and more.

This app allows users to see the progress of a bill of materials, and apply filters to focus on parts that are not yet released. It is also useful for viewing all of the “make” parts or “buy” parts in a given BoM, or all parts created/modified by a particular user.

Get better access to your product data

See all the features of EAC P