Part II – (You can read part 1 here) Evolving your BoM strategy, tools, and abilities. “EBoM vs. MBoM” transforms into “EBoM integrates with MBoM.” This integration includes associativity to one another, time saving tools, elimination of error prone manual steps & more.

Imagine eliminating the common disjointed processes, additional time, and error prone manual steps involved in the creation of downstream BoMs from Engineering into Manufacturing, Production and Service management.

Concepts & examples such as Manufacturing Bill of Materials (MBoM) are shown below, all under one system, integrated & associated, and created with a single click. Then they’re easily edited to meet downstream BoM needs.

BoM creation can be streamlined & improved by associatively creating downstream BoMs (S or M or other) and eventually, connecting them to your ERP system. For now, we’ll focus on the first step of this business transformation concept; the creation of the second, or downstream M or SBoM, starting with a simple EBoM example, created in minutes, and easily viewed & tracked.

Who should be involved in this topic at your company? Ideally, your Configuration Manager role should be leading or heavily involved in this process.

The starting point & tool is PTCs Windchill and your willingness to change & improve.

Once your CAD data is ready to check into Windchill, there is an option (check box) to auto-associate the EBoM to a downstream BoM such as an MBoM. It is a 1:1 relationship for starters. Options can branch out from here into many CM (Configuration Management) directions. Such as multi-level BoM management, uses, visualization and more.

Once created, you can manipulate & edit the default 1:1 downstream BoM to your needs; adding bulk items, manufacturing specific sub assemblies, (build throughs) even new service end items. You can also flatten out an EBoM to meet assembly or production needs. BoM items such as adhesive, lubricant, paint or coatings, packaging items, all things that typically are not on an EBoM, can and do belong on the M or SBoM.

If this fits your company’s needs? consider using Windchill’s auto-associate feature.

This article covers a couple examples. If this is not deep enough…here are even more tools to consider. Topics such as creating associated manufacturing instructions, work instructions, work plans and more. Change Management is shown as reference only, it is an optional element of Windchill for another blog.

There are many options to this topic, these are common examples that fit a lot of needs and is considered a starting point.

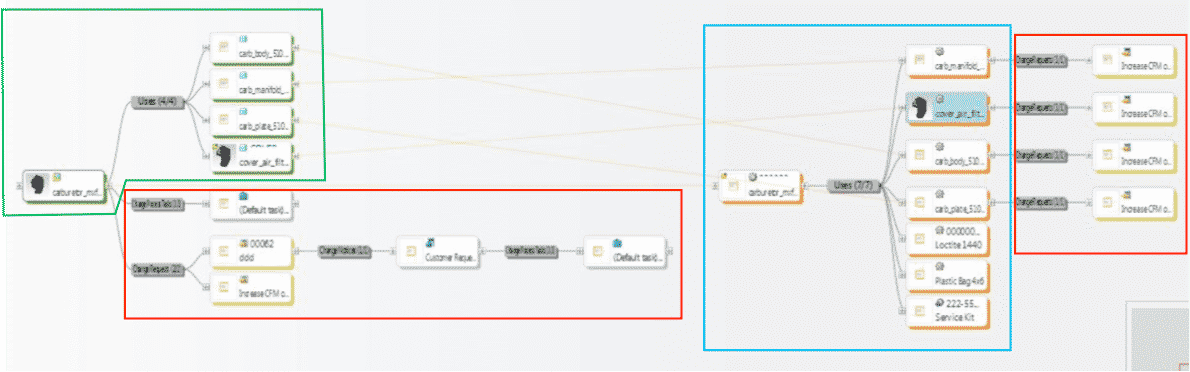

1stexample shows all BoM & change components all connected in one system vs. manually done in silo fashion, which is industry’s most common method today. These examples are shown in PTCs Windchill reference viewer tool, which ties all related objects into view for easy visibility with just a few clicks.

- 1. EBoM structure (highlighted in green)

- 2. Change requests, notices and tasks (highlighted in red)

- 3. MBoM structure (highlighted in blue) with their own, or connected Change Management Requests, Notices & Tasks

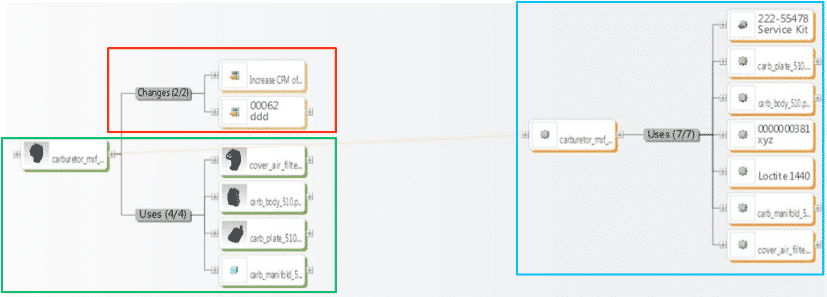

2ndexample shows an EBoM, SBoM (Service Kit in this example), with a saleable end item service kit, as well as components for service or manufacturing BoMs. It also shows Changes, these can also be created, edited, routed, approved or rejected, and even include the SBoM if need be.

Please connect with EAC to learn more, to discover your company’s transformation opportunities with an assessment, maybe see a demo, or attend a webinar. The goal is to help your company transform how you design, manufacture, connect to and service your products.

I’d like to start off by clarifying the difference between eBoM vs eBoM. Most companies developing products have both an eBoM and mBoM.

- Engineering Bill of Materials (eBoM) — as designed

- Manufacturing Bill of Materials (mBoM) — as shipped

You may not agree, many don’t see it this clearly. The industry does, and therefore, some software tools have more ability than you may know. But, I guarantee, if you overlay these two elements onto what you are doing for Bill of Materials (BoMs), whether in Engineering, or in Manufacturing, or in Production, you’ll see the clarity of these two simple elements rise to the surface.

Definition of eBoM and mBoM:

eBoMs are created in engineering, are typically driven from the CAD tool, and are usually centric to the final assemblies list of parts or components that make up the as designed or eBoM.

mBoMs will contain, or be ‘driven’ by the eBoM. MBoMs make up the ‘end item’, or product as shipped. Of course, the eBoM, or ‘parts list’…the eBoM requires additional things like shipping containers, crates, peanuts, or packing foam, plastic bags for accessories, power cords, or items necessary to complete the product that is not defined on the eBoM.

Manual processes for eBoMs & mBoMs

In the drawing board days, we often communicated this detail as a table on the final assembly drawing. Sometimes as many sheets attached or referred to on the final assembly drawing. Hopefully, you’ve evolved beyond that! If not, that’s okay, there is hope. Unfortunately, many still use this legacy approach and are still creating (painfully) this table on their CAD assembly drawings. Others may be manually forming them in spreadsheet software.

The next step, and pain point, you must re-enter or get the data into your ERP/MRP tool. Either manually, or via an importation, it is error-prone. What if changes occur? But, that never happens, right?? Ha.

How much time does your organization spend on these tasks? How about errors because of changes? Do you have the role of Configuration Manager defined?

The task of creating the mBoM from the eBoM usually has many manual and painful disjointed steps. Often involving exporting out of one tool, into another, but only if you are evolved enough — as I stated earlier, many are not this evolved, but have the vision to do so…maybe you’ve already made a connection from your data management tool to your ERP/MRP system?

PLM Systems like PTC Windchill help you manage your BoMs

EAC can help you form this vision, and guide you to a better way of understanding this topic in the context of your organization. We strongly believe there is a better way to develop products – and managing eBoMs and mBoMs is just one part of doing it better.

PTC Windchill can drive the eBoM into the mBoM or vice versa. It has the out of the box ability to be the tool for the Configuration Manager roles in your organization. Options and variants are another use case you’ll see in a future blog topic.

Organizations have found ways to leverage PLM systems that transform their product development process and defeat pain points like the disjointed processes that come with manual creation of the mBoM from the eBoM.

Take a look at the Aberdeen PLM Research revealing that organizations with connected PLM see a 22% increase in engineering productivity and 21% improvement.

If you’re looking for a PLM solution such as PTC Windchill, our Product Development System Services (PDSS) team can help implement the software within your organization.

Download our free eBook on Designing an Effective Change Control Process to help understand the digital transformation movement better.