- Reduced brittle failures: Increased elongation by more than 100%.

- Improved strength and stiffness: Increased flexural strength and flexural modulus by roughly 15%.

- Better performance at elevated temperatures: Increased heat deflection temperature by roughly 25%.

- Professional-looking parts: New grey color.

Formlabs is making their Tough resin even tougher – with a reformation – offering Tough 2000 as the more advanced 3D printing material.

Formlabs and EAC will continue to sell the Tough resin until it is sold out – then it will be replaced with Tough 2000. If you’ve been using Tough resin – it will be available through the end of 2020.

You can use the Tough 2000 resin on Formlabs desktop stereolithography (SLA) 3D printers – specifically on the Form 3+.

Tough 2000 vs Tough

Compared to Tough Resin, this material reformulation brings:

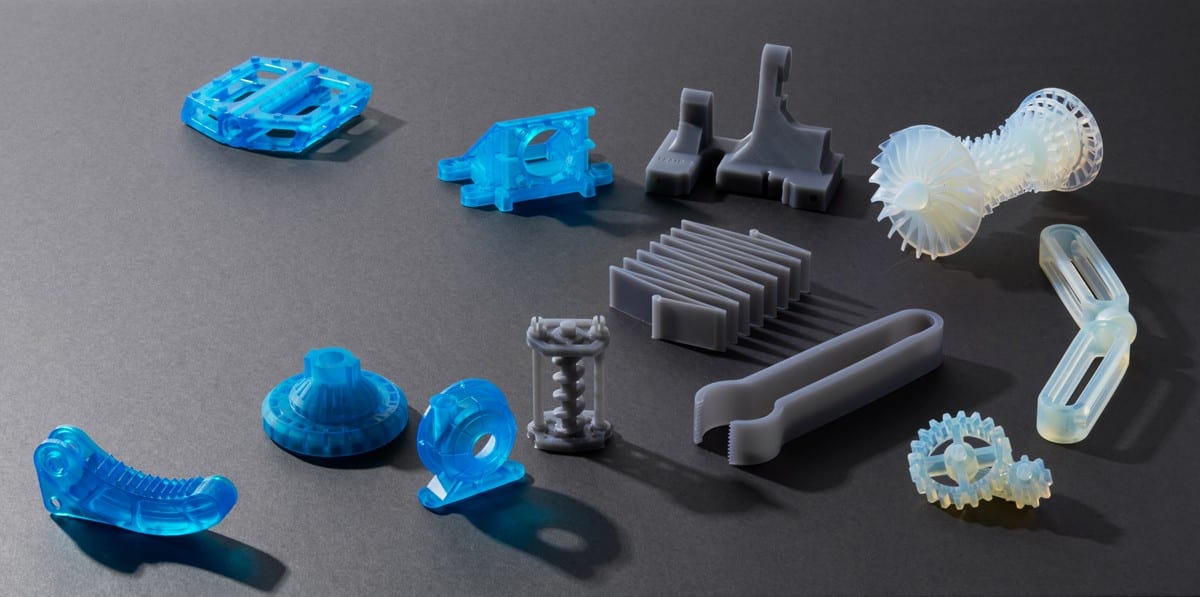

Tough 2000 Resin is the strongest and stiffest material in the functional family of Tough and Durable Resins, with “2000” representing the material’s tensile modulus. The resin is improved elongation, strength, and stiffness, which are typically competing mechanical properties.

Due to its high strength and modulus, Tough 2000 Resin can handle higher stress and will hold its shape better under load compared to Tough 1500 or Durable Resins. When pushed to its stress limit, Tough 2000 parts will bend significantly before ultimately breaking.

Note that Tough 2000 Resin requires specialty resin tanks, Form 2 LT Tank or Form 3 Tank v2.

Other Tough and Durable Resins

This video clip shows a stress test between the Tough 2000, Tough 1500, and Durable Formlabs resins.

Tough 1500 Resin is the most resilient material and is ideal for: prototypes that repeatedly bend and quickly return to shape; jigs and fixtures requiring repeated deflection; and simulating the strength and stiffness of polypropylene (PP).

Durable Resin is the most pliable, impact resistant, and lubricious material and is ideal for: squeezable prototypes and low friction assemblies; non-degrading surfaces as a result of repeated wear; jigs and fixtures that will experience significant impacts; and simulating the strength and stiffness of HD/LD polyethylene (PE).

When should I use Tough 2000 resin?

Tough 2000 Resin offers more advanced mechanical properties and a new dark grey look. It is ideal for:

- Strong and stiff prototypes

- Jigs and fixtures requiring minimal deflection

- Simulating the strength and stiffness of ABS

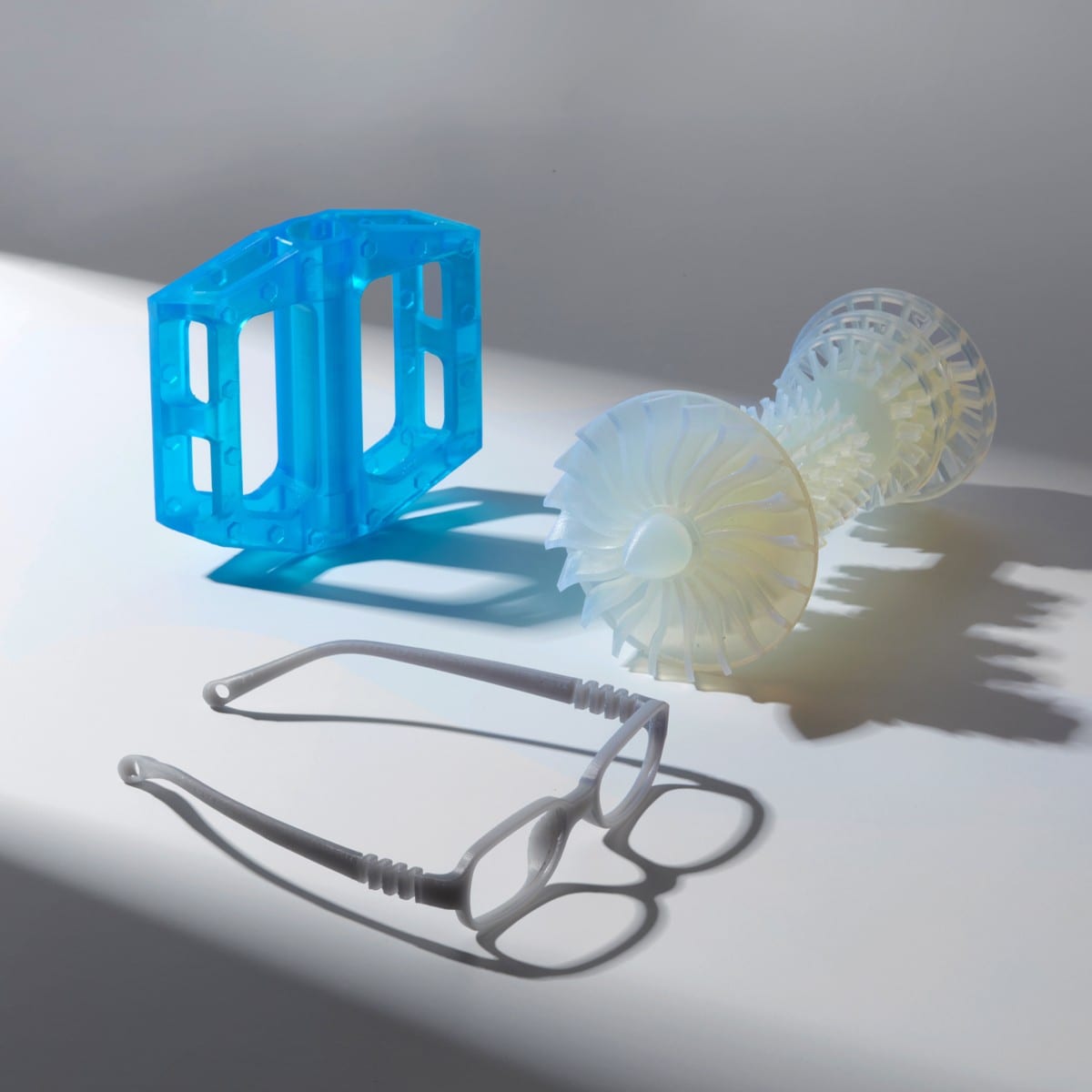

Choose Tough 2000 Resin for prototyping strong and sturdy parts that should not bend easily, such as housings and enclosures, jigs and fixtures, mechanical connectors, and prototypes undergoing wear and tear.

You can use this resin with applications across engineering, product design, and manufacturing. Tough 2000 resin can be printed for prototypes undergoing wear and tear, mechanical connectors, and housing and enclosures such as the below motor mount.

The improved strength, stiffness, and elongation allow engineers and product designers to iterate with higher confidence and reduce brittle failures.

Download the Tough 2000 resin data sheet to read on material properties and tech stats.

This video clip shows a motor threading with the Tough 2000 resin.

Where to find Tough 2000 Resin

You can find Tough 2000 resin in our Formlabs Resin Library where you can either order a sample part or order the actual resin.

Formlabs is adding to their Tough and Durable family of engineering resins – they’ve released the Tough 1500 resin recently – and it’s the most resilient material they have.

You can use Tough 1500 resin on your Form 3+ SLA 3D printer.

Tough 1500 Resin for Resilient Prototyping

Tough 1500 Resin is also the most robust, functional, and dynamic group of materials. Choose this resin for parts undergoing bending, tension, compression, or impacts that will bend or deform slightly before breaking. It produces stiff and pliable parts that bend and spring back quickly under cyclic loading.

The family of Tough and Durable Resins share numerous characteristics and is great for functional prototypes, jigs and fixtures, connectors, and other shared applications. Identifying the best material for your specific use case involves understanding your design constraints and the key tradeoffs between the materials.

Tough 1500 Resin is ideal for:

- Prototypes that repeatedly bend and quickly return to shape

- Jigs and fixtures requiring repeated deflection

- Simulating the strength and stiffness of polypropylene (PP)

Due to its high elongation and moderate modulus Tough 1500 Resin is ideal for parts that bend, but require high memory retention. When pushed to its stress limit, Tough 1500 parts will strain significantly before permanently deforming and ultimately breaking.

Download the Tough 1500 resin data sheet to get more details on material specifications and tech stats.

Why was there a need for another tough 3D printing resin?

“Unfortunately Tough is WAY too brittle in a lot of applications!”

“I see a bit of a sag with Durable after the print finishes.”

These are direct quotes from one of Formlabs customers when using the only existing engineering resins at the time. Formlabs understood there was a gap in the Engineering family and decided to add the Tough 1500 resin to stay competitive in the market and to increase their value proposition to customers.

Customer Testimonial for Tough 1500 Resin – Unplugged Performance

Unplugged Performance is the world leader in premium performance upgrades for Tesla vehicles. Some of these upgrades involve installing customized car bumpers.

Before 3D printing, it would take Unplugged Performance roughly 45 minutes to remove each sensor mount from the existing bumper and another 10 minutes to bond it onto the new bumper. At six sensors per car, in addition to other custom upgrades, they were only able to complete one car every one-and-a-half days.

With their Formlabs printer, Unplugged Performance now prints new sensor mounts in batches of 30. This eliminates the costly time spent removing the sensor mounts from the existing bumper and leaves them with only the bonding step of their workflow. This helped improve their throughput to three cars per day.

Unplugged Performance uses Tough 1500 Resin for the printed mounts due to its compliant nature, which enables it to clip onto and secure the various sensors. Tough 1500 Resin’s high impact strength enables safe mounting of the sensors in the car’s bumper as well.

Unplugged Performance also prefers the grey color of Tough 1500 Resin compared to Tough Resin and Durable Resin. This has opened up new opportunities to create visible custom parts that blend seamlessly into the car’s interior.

How to order Tough 1500 Resin

Check out our Formlabs Resin Library where you can order a free sample part or order the resin if you’ve already decided it will work for your application. Watch this video of our Additive Manufacturing Specialist with a part made from Tough 1500 – which would be the exact part you’d receive if you order the free sample.

Follow Lauren on LinkedIn for more Formlabs tips and tricks.

Here are the top 10 blogs that our readers loved from this year:

10. Form 3B: Formlabs New Biocompatible 3D Printer

Formlabs released a new Form 3B 3D printer for biocompatible materials. Read the blog if you’re interested in:

- Knowing the difference between the Form 3 and the Form 3B

- Form 3B 3D printer price

- Resin compatibility with the Form 3B

- Ordering free dental sample parts

9. New Soft, Elastic Engineering Resin from Formlabs

Formlabs released a new Elastic Resin – highly elastic and strong material for prototypes and parts. This new resin is a long-lasting, tear-resistant, and made of resilient material that can withstand repeated use. You may be interested in knowing more if you can relate to these use cases:

- Wearables and consumer goods prototyping

- Medical visual simulation and devices

- Compliant features for robotics

- Special effects props and models

8. PLM Apps Benefit Business

Most companies lose a lot of time and money when employees are challenged with finding relevant, up-to-date product data. According to the Harvard Business Review, workers waste approximately 50% of their time locating data, finding and correcting errors, and searching for sources to confirm the accuracy of data. PLM Apps can help.

If you manage PLM systems and organize CAD data within your company you’ll find this blog helpful. In it you’ll read about:

- How PLM apps are meant for ease-of-use with your PLM system

- How multiple PLM softwares can be integrated

- How PLM apps controls security and access to desired teams

- How customized PLM apps can align with your business strategy

7. ERP vs PLM – What’s the Difference?

We have you take a deep dive into your digital transformation initiatives – which in return, will help you develop the skills to choose the right technology for your organization. This blog breaks down:

- What’s trending in ERP & PLM enterprise systems

- The differences and similarities between ERP & PLM

- How you can use ERP & PLM together for most impactful ROI

- PTC Windchill PLM software and its integration with other systems

6. Bill of Materials Management- What You Need to Know

If you have experience with bill of materials (BoMs) or are just learning about it – you may want to brush up on the info in this blog. We cover:

- Defining bill of materials: ebom, mbom, and sbom

- Importance of accurate BoM processes and reporting

- How BoM management plays a role in system integration

- Custom bill of materials app – BoM Reports

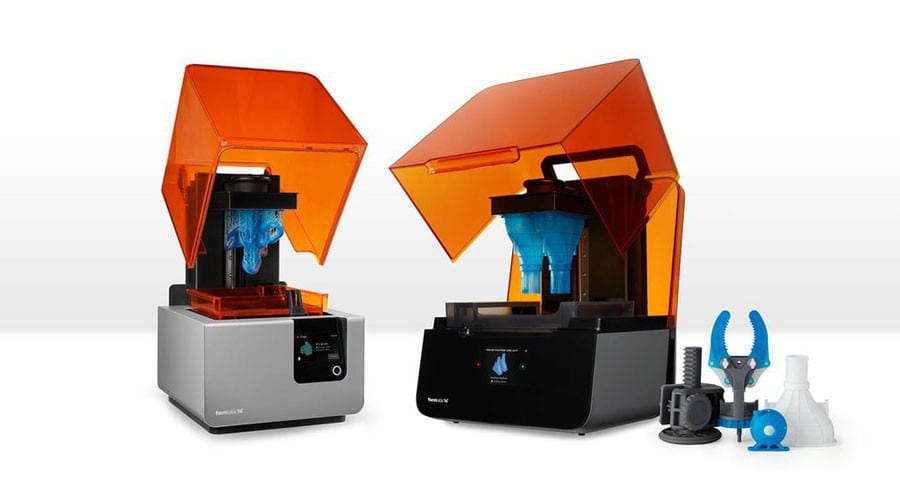

5. Formlabs Releases New 3D Printers using LFS Technology

Formlabs retired the Form 2 SLA desktop 3D printer and released 2 new printers at the beginning of the year – the Form 3 and Form 3L. Read this blog to find the answers to these questions:

- What are SLA and LFS 3D printing? And how the processes different?

- What other technologies are leveraged with LFS?

- What are the benefits of LFS 3D printing?

- What is an LPU and why does it matter?

4. PTC Mathcad Prime 6.0 is here!

Mathcad 6.0 is the newest release of PTC’s engineering calculations software for engineers. The release is meant to help improve your productivity and overall usability to make your job easier every day when it comes to math notations in product development.

Here are some of the new improvements:

- Customized margin dimensions, including headers and footers

- Spellcheck, multi-language keyboard, and hyperlinks have been added

- 2D ChartApp options such as exporting your plot as an image file

- New symbolic calculation engine

3. Form 2 vs Form 3: Formlabs SLA 3D printer comparison

If you’re wondering how the Form 3 compares to the Form 2, we’re able to tell you the differences between the two Formlabs 3D printing machines. The Form 2 is no longer available for purchase – but we’ll point out the improvements in the Form 3 (which IS available for purchase) such as:

- Why LFS (Form 3) is better technology than SLA (Form 2)

- Easier support removal for nearly finished prints

- Flexible tank reduces stress during peeling process

- More precise detail and quality 3D prints

2. Formlabs Form 3 & Form 3L: Answers to your FAQs

- How accurate is the Form 3? How fast is the Form 3?

- How much bigger is the Form 3L build volume?

- What are the biggest differences between Form 2 and Form 3?

- What parts are cross-compatible between Form 2 and Form 3?

1. What is PTC Windchill Software?

If you’re looking for a new PLM system to add to your organization – try PTC’s Windchill. We’ll break down everything you need to know including:

- What’s the origin of PTC Windchill software?

- How much does Windchill PLM cost?

- PLM products: PDM Essentials, PDMLink, ProjectLink, PartsLink

- Admin, support (Alliance Program), and certified training

Formlabs new 3D printer, the Form 3B, is an advanced stereolithography (SLA) desktop 3D printer optimized for biocompatible (thus, the ‘B’ in Form 3B) materials (resins) and validated workflows.

Form 3B vs Form 3: Which one should I use?

If you are an early adopter and you have already purchased a Form 3 before November 12th of 2019, then you can print all compatible resins on your Form 3 (or Form 2). If you purchase a Formlabs 3D printer AFTER November 12th of 2019, then you have two options.

Form 3B: Exclusively prints ONLY biocompatible resins (surgical guides, hearing devices, etc.)

Form 3: Prints only non-biocompatible resins (anatomical models, device prototypes, etc.)

Form 3B Price

The Form 3B is a little more expensive than the Form 3 – The Form 3 Basic Package starts at $3,499, whereas the Form 3B Basic Package starts at $4,999.

The Form 3B Basic Package includes the 3D printer, Finish Kit, Build, and Tank.

New Surgical Guide Resin

The newest surgical guide resin is an autoclavable, biocompatible resin for 3D printing surgical guides for implant placement. This next generation 3D printing material is for premium-quality surgical implant guides.

This resin is only available for the Form 2, Form 3B, and early 2019 Form 3 printers.

When speaking to beta testers, we found they enjoyed the print clarity, superior mechanical properties, and improved accuracy of the Surgical Guide Resin.

The Surgical Guide Resin is sold at $249.00 per liter and is ideal for:

- Surgical guides

- Drilling templates

- Pilot drill guides

- Device sizing templates

Available for the Form 3 (Early 2019), Form 3B, and the Form 2. It is not available with the Form 3 (non-biocompatible, purchased after Nov 12).

What does this look like in PreForm software?

Formlabs 3D printing software, PreForm, will update with the PreForm 3.1.3 version and will include print setting for the following resins on Form 3B and early 2019 Form 3:

- Surgical Guide Resin, 100 microns

- Grey Resin, 160 microns

The PreForm software will also include the following printer model options:

- Form 2

- Form 3 (early 2019)

- Form 3B

The 'regular' Form 3 (model released after Nov 12, 2019) will come at a later date.

Form 3B

Formlabs 3D Printer: Form 3

What makes the Form 3 the best 3D printer out there?

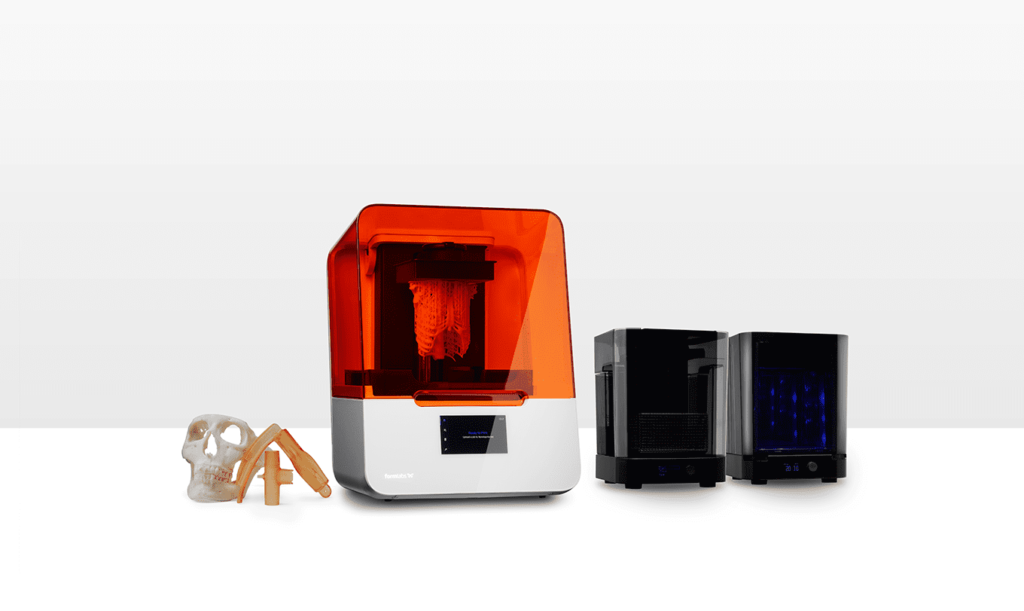

The Form 3 combines a flexible tank and linear illumination to deliver incredible print quality and printer reliability through a new Low Force Stereolithography (LFS) process.

The flexible tank lowers the forces exerted on the part during printing to provide incredible detail and surface finish, and allows for light-touch support structures that easily tear away. The Light Processing Unit uses a system of lenses and mirrors to direct a precise, uniform high-density laser spot.

How accurate is the Form 3?

The Form 3 prints with 25 micron XY resolution and 25-300 microns (user selectable) in the Z, using an 85-micron laser. Accuracy depends on many factors such as the print performance of an individual resin.

How fast is the Form 3?

The Form 3 delivers the perfect balance of detail and speed. Print times will be comparable to Form 2. A new material, called Draft Resin, was specifically developed for fast printing at 300-micron layers for engineering parts where a fast turnaround is critical.

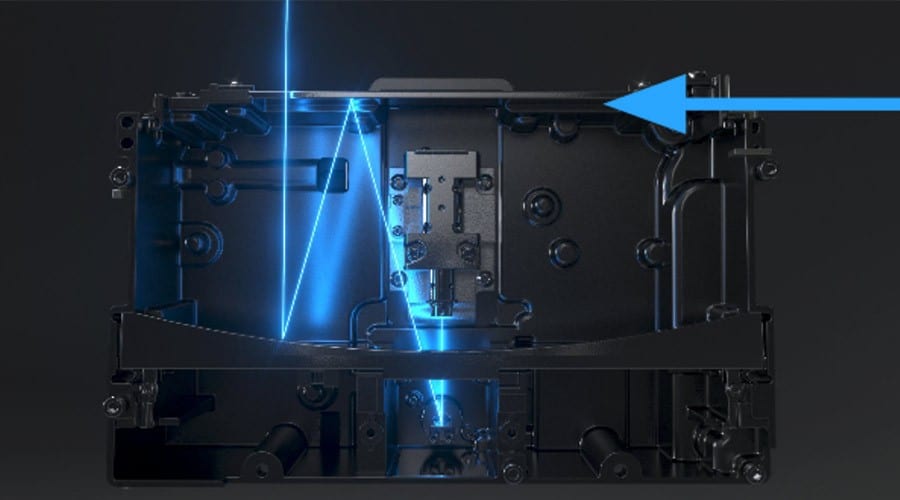

How does the optics module work?

The custom-designed Light Processing Unit (LPU) inside the printer is built to deliver accurate, repeatable prints, using a compact system of lenses and mirrors. During printing, the LPU moves in the X direction, while the high-frequency galvanometer inside positions the laser beam in the Y direction, then directs it across a fold mirror and parabolic mirror to deliver a beam that is always perpendicular to the build plane. The high-power-density laser is passed through a spatial filter to guarantee a clean laser spot.

What layer thicknesses are available for Form 3?

25 – 300 microns (.001 – .012 in) . See Form 3 tech specs here.

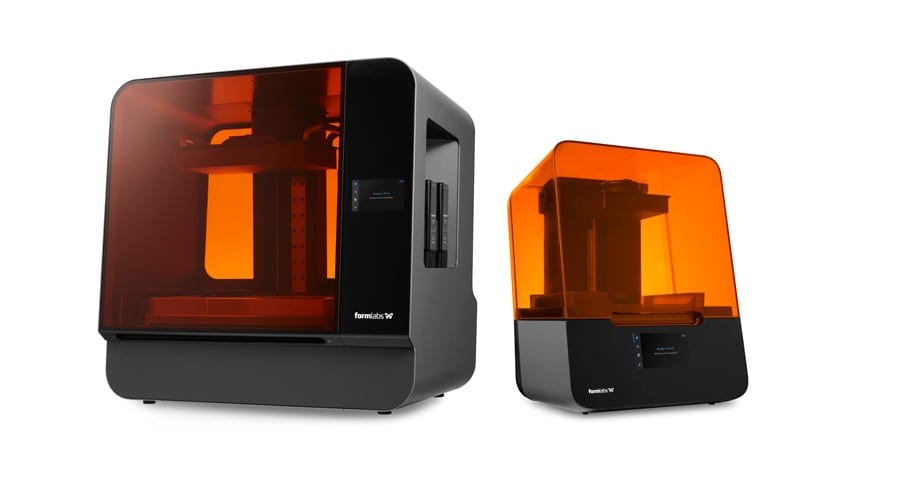

Formlabs 3D Printer: Form 3L

How much bigger is the Form 3L build volume?

Five times bigger than Formlabs’ desktop printers: W x D x H: 33.5 × 20 × 30 cm (13.2 × 7.9 × 11.8 in)

How does the build volume for Form 3 compare to Form 2?

The Form 3 has the same XY (145 x 145 mm) as the Form 2 with a slightly larger Z (185 mm versus 175 mm). See the comparable tech specs here.

What are the biggest differences between Form 2 and Form 3?

The Form 3 is built around a new print process called Low Force Stereolithography. Reducing the forces on parts is key to taking a big leap forward in part quality and printer reliability.

Formlabs has made the core optics more powerful, robust, and easier to monitor and maintain with the enclosed Light Processing Unit. A series of filters, sensors, and mirrors ensure uniform light for greater precision and better performance over time.

They’ve also added many sensors that help with overall usability, from correcting user error with a UI guided onboarding process, to more precisely measuring remaining resin.

Finally, there are some great features designed to save time, increase throughput and enable new ways of working. Like fine touch supports that reduce part finishing time and improve underside surface finish, and the ability to prime a printer to remotely start a print overnight, allowing you to respond to just in time requests.

That said: the Form 2 is an award-winning, tried-and-true machine, and is now available at an even more affordable price point.

How does the Form 3 peel force compare to the Form 2?

The force on a part depends on the part geometry and material. In their internal testing, Formlabs has seen force reductions anywhere from 3 – 10x compared to the Form 2. Reducing the forces on parts while printing allows you to print with fewer and lighter supports. Lower forces also allow us to better capture fine detail and smooth surfaces with minimal layer lines, and result in improved print success and overall reliability.

What parts are cross-compatible between Form 2 and Form 3?

Many components are cross-compatible between the two printers. The build platform, resin cartridges, Form Wash and Form Cure, PreForm, and Dashboard are compatible across both machines. The standard Finish Kits are comparable with the addition of the tank tool for Form 3.

These are the most frequently asked questions for Formlabs’ new 3D printers, the Form 3 and the Form 3L. Please reach out if you have any questions that weren’t answered here.

Don’t forget to follow me on LinkedIn to check out my tips and tricks on how to use Formlabs 3D printers and trends in the additive manufacturing industry!

The Form Wash is designed for the Form 2 3D printer from Formlabs to automate the cleaning process between printing parts. It makes things much easier for engineers who don’t want to waste any time cleaning their prototypes so they can either use the Form 2 again for another print job or get back to their next project.

Washing printed parts before post-curing helps to remove excess residual resin from part surfaces and cavities. Formlabs suggests using isopropyl alcohol (IPA) as the solvent that is most compatible with washing.

If you take a look at the image above, you can see that the left part is much cleaner and visually is more detailed than its counterpart. After using the Form Wash, you can typically use the Form Cure to expose printed parts to light and heat to stabilize the parts for performance. Using the Form Cure is not necessary but using the Form Wash and Form Cure together is recommended for optimal finishing.

Colder Products Company (CPC) has trusted EAC for years to provide them multiple Form 2 printers and other Formlabs equipment and materials to rapidly prototype customized quick disconnect couplings, fittings, and connectors for plastic tubing used around the globe. We answer a few questions that users have about the Form 2 and also include an engineer’s intake as well. Here is how Jeff Martin, an applications engineer at CPC, uses the Form Wash in-house to reduce time spent cleaning 3D printed parts.

How much time does it take for one wash?

Formlabs says that most resins require washing for the Form Wash default programmed time, which is 10 minutes – although additional time is needed for some resins. The following table shows Formlabs’ recommended wash times for each resin being used.

| Resin | Wash Time | Resin | Wash Time |

| Tough | 20 min | Elastic | 10 min + 10 min |

| Rigid | 15 min | Dental SG | 5 min |

| Grey Pro | 15 min | Dental LT Clear | 5 min |

| Castable | 10 min | Denture Teeth & Base | 10 min |

| Castable Wax | 10 min | Ceramic | 5 min |

| High Temp | 6 min | All other resins | 10 min |

Jeff suggests that you should set your wash time at 20 minutes for each wash. He also recommends that it’s best to physically have 2 Form Washes in-house to speed up the cleaning process, “The first Form Wash set to 10 minutes to wash parts hanging from the build platform, and the second Form Wash is used to clean the parts broken free from supports.” (Keep in mind, he typically uses Rigid Resin for his 3D prints).

What’s the best way to wash prototypes?

If you’re using the Finishing Kit, Formlabs recommends that you should wash your prototypes in at least two standard wash tanks – the first wash, being the ‘dirty’ wash, would take 10 minutes and then the second wash, using a cleaner tank, for another 10 minutes. Once the first tank gets dirty, you can dispose the IPA, transfer the second tank into the first tank, and then pour new alcohol into the second tank.

The Finishing Kit includes 2 wash tubs to manually clean your 3D prints – whereas the Form Wash automatically cleans your parts and prototypes.

Jeff says the advantage of having a second Form Wash is that you can use Formlabs’ same theory of having a clean tank to do the final rinse. “I find it in my experience to be extremely useful to remove the supports for the second wash. The reason is that the supports block the fresh circulation of clean solvent from the parts. You will notice that for deep aspect bores and blind holes, if you do not remove the supports, they often times will not fully be cleaned of resin. After removing the supports and letting the parts bounce around in the basket during the last 10 minutes, they will always come out clean.”

Learn more FAQ by reading our related blog, “Everything You Need to Know About the Form 2 3D Printer.” If you’re interested in a free sample, then contact us at your earliest convenience.

Also, follow me on LinkedIn for tips and tricks on how to use the Form 2 and other equipment and materials from Formlabs!