- Reuse and instrument released designs

- Embed sensors into new designs

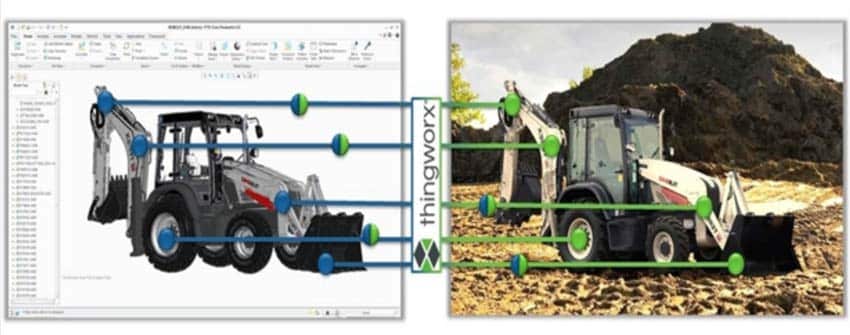

- Connect CAD models via digital twins to real-world data

- Use real-world sensor data in CAD design

- Integration with ThingWorx, the world’s leading industrial IoT platform

- Prepare for Product as a Service

Remember in 1977 when Ken Olson, the founder of Digital Equipment Corporation said, “there is no reason anyone would want a computer in their home”? Boy was he wrong. Not even a leader in the technology industry could predict how quickly our usage of technology would change.

If you don’t make an effort to keep up with the fast pace of technology; you will fall behind. It’s critical that you proactively embrace and move towards digital processes to ensure that future products better meet the needs of customers.

What better way to keep up with the future than making highly accurate product performance and behavior predictions with the right design tools?

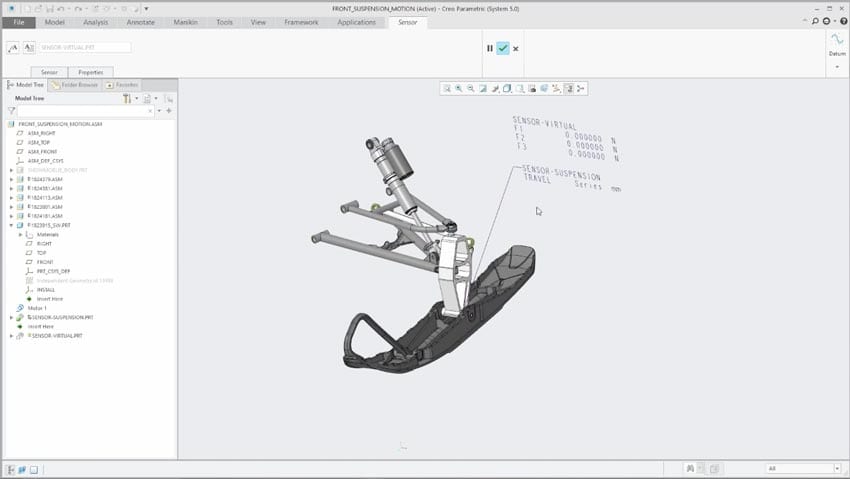

PTC developed a Creo extension called Creo Product Insight. It lets designers and engineers incorporate the latest sensor technology into their designs.

What is Creo Product Insight?

Creo Product Insight captures and analyzes product data from live sensors on prototypes and products directly within your CAD model. This tool produces a digital twin, an exact replica of a physical prototype in a virtual CAD model, to mirror the performance of a product under real-world conditions.

How does it work? You add digital sensors from a library directly into your CAD models in Creo. Then you connect them to the data streams from physical products. Whether you’re looking to get more value out of your prototypes, design smart connected products, or use data to improve the quality of existing products, the Creo Product Insight Extension allows you to design smarter.

So how are organizations keeping up with the digital transformation with the Creo Product Insight Extension?

Improving New Product Design

When you’re improving new product design you’re most likely basing your design decision on assumptions and historical data. This puts you in a difficult spot because you may not have up-to-date-information which may cause inaccurate solutions and error-prone results.

Creo Product Insight allows you to validate design assumptions using real-world data from the field directly in Creo’s simulation and analysis tools. Using this extension also decreases your reliance on building prototypes because it gives you live product performance and behavior.

Improving Existing and Next-Generation Product Designs

The absence of real-world product data stunts the optimization of current and future products. If you had access to real-world data, you would be able to validate design criteria against customer usage data and mitigate risk of product failure, warranty, repair, and liability.

With Creo Product Insight and ThingWorx you can analyze field data and provide meaningful information back to engineering. Using real-world data allows you to identify opportunities for new products in the market and understand over and under engineered designs to reduce product life cycle costs.

Improving Smart Connected Product Design

The lack of specialized tools that support smart connected products puts you at risk of falling behind the digital transformation process. When sensors and a strategy to capture real-live data are disconnected from your design process there is no way to deliver the value that your customers deserve out of their products.

Creo Product Insight gives you the ability to optimize sensor replacements, choose a sensor type, and validate data capture requirement during the design process. The extension creates an integrated design process that delivers optimal value from smart connected products.

Creo Product Insight Capabilities and Benefits

Capabilities:

Benefits

- Eliminate manual workflows to use real-world sensor data in design

- Optimize products to real-world conditions

- Ensure that future products better meet the needs of customers

- Creo analyses outside of the design office

- Decrease reliance on physical prototyping

Creo Product Insight Licensing and Creo Version Capabilities

The Creo Product Insight is an add-on extension that is available for subscription licensing only. You do not need ThingWorx to use this extension – although using ThingWorx with it will fully optimize your results.

“Physical” Sensors – Creo 4 (M020):

- Easily define and place ‘measure’ sensors by adding physical sensors to Creo Assemblies

- New Instrumented sub-type to protect reused/released design data

- Associated parameter and input definitions and associated calculations

- Define (physical) calculating sensors (M020) to report analysis results (center of gravity, mass, area, etc.)

UX Sensors – Creo 4 (M030 & M040):

- Connection to ThingWorx to support reporting analyses results (M040)

- Run Creo analysis using Behavioral Modeling, Simulation, and Mechanism Dynamics (M040)

- Read real-world data from ThingWorx (or CSV data file) and use input variables to run analyses and report results back to data tables

“Virtual” Sensors – Creo 4 (M050):

- Specialized Virtual sensor handling – (excluded from BOM, meshing, and graphics)

- Directly connect and read sensor data from file or ThingWorx

- Use real-world sensor data to drive simulations

- Creo as a Service from ThingWorx (M050)

- Save/Export analysis results together with input values back to data file

Get live data from CAD models

Download the Creo Product Insight datasheet or watch this webinar replay to learn more and see if your organization could benefit from collecting live data directly within your CAD models. I’m willing to bet it can.

There’s a lot of buzz around the Internet of Things (IoT) these days and the phrases getting manufactured and tossed around are confusing a lot of my friends.

1. Smart Connected Product (SCP)- one product in many places.

2. Smart Connected Operation (SCO)– many assets, typically machines, in one place.

3. Smart Connected Enterprise (SCE) – real-time access and visibility to existing silos of data and information.

Smart connected operations are transforming companies and changing the way we do business.

Imagine if your company was able to take advantage of data that revealed existing and future problems, and allowed your team to make drastic improvements by completing predictive maintenance and service.

Business decisions can no longer be reactive. You need to be proactive — Here’s how smart connected operations could ‘revolutionize’ the way you do business.

Smart connected operations help businesses make faster decisions

What helps a company make fast, highly informed decisions? Data.

Smart connected operations allow information to be collected from multiple sources, assets, facilities, and even vendors. This connectivity allows data to be collected and analyzed to inform decision-making and enable teams to make faster decisions.

Smart connected operations help businesses increase operational performance

Smart connected operations can help your business monitor and track asset viability, ultimately allowing your company to reduce downtime, improve design, and improve utilization.

Data from connected assets, in collaboration with other enterprise systems, can provide not previously possible visibility and automation across organizations.

For example, product data flowing through a CRM system can also be sent to billing or into a supply chain management system— helping to eliminate error-prone manual steps and providing new sales opportunities for things such as consumable replenishment or warranty renewals. (PTC)

Smart connected operations help businesses decrease lead time and increase product quality

The insight smart connected operations provide will help you improve and perfect your production processes.

By integrating smart technologies and processes, your organization can lower development costs, time-to-market, and improve your overall product quality.

Smart connected operations help businesses improve manufacturing responsiveness

A sensorized manufacturing floor let’s you monitor performance, in real-time, and provide valuable information to field service technicians and manufacturing floor managers.

Service responsiveness will be accelerated with remote monitoring, access, and complete management of your disparate systems through enabling smart connected operations within manufacturing.

Smart connected operations help businesses improve supply chain coordination

The new capabilities of smart, connected operations will alter every activity in the supply chain.

Your operational efficiency will increase exponentially if your organization reaps the benefits of integrating with other data, such as inventory locations, traffic patterns, commodity prices, and historical data repositories.

Smart connected operations help businesses reduce manufacturing IT costs

Smart connected operations use digital interfaces that make it easier and less expensive to track the production process. These interfaces are less costly to apply and easier to modify than physical system controls. By integrating smart connected operations, your company will increase operation mobility, which in turn can reduce your manufacturing IT costs.

The sensors in smart connected operations also identify a need for service before the machine or product fails. These data analytics will drive previously unattainable efficiency improvements by providing predictive maintenance analytics and higher productivity levels.

With the help of predictive analytics, smart connected operations help organizations anticipate problems and take early action.

For example, your industrial machines would be remotely monitored and adjusted by end users during and beyond operation hours. They could even begin to manage themselves leveraging machine learning and predictive analytic engines.

The bottom line is that smart connected operations have begun to change business models, organizational structure, and manufacturing system architecture.

The development and the deployment of smart connected operations will be incremental, but the opportunity is here today.

What are you waiting for? It’s time to start capturing the time, dollars, production, and quality that smart connected operations can provide.

It is not too bold to say the Internet of Things (IoT) is just about everywhere. Some even say that IoT will have a greater impact on business and productivity than the introduction of the Internet itself.

Whether you embrace it or attempt to look past it, the wave of IoT has already started disrupting many industries.

So what exactly is the Internet of Things? Well, if you haven’t read the HBR article by Michael Porter and Jim Heppelmann, I encourage you to do so.

I am referring to the concept that our physical and digital worlds, in which we have always compartmentalized into separate realities, have begun to converge into a single new reality.

This new reality with the IoT has started to change the way we do business.

Our strategies have begun to take our physical products, parts components and factories, and connect them to our digital systems.

This has allowed us to collect data, analytics, performance measures and much more.

Although there is so much that you can learn about IoT, Here are 10 things you need to know about the Internet of Things.

1. IoT Can Fuel Your Existing Business Initiatives

The Internet Things should not be thought about as something separate and distinct from your business strategy, but rather as an opportunity filled with unlimited capabilities.

This revelation could possibly be the exact catalyst needed to meet your existing business initiatives.

No matter what your business is specifically looking to achieve, IoT can be a real game-changer.

Some businesses have used smart connected operations to discover efficiencies while reducing risk.

Others have integrated smart connected products by modifying and creating new assets and services to increase revenue.

I have also seen companies incorporate smart connected solutions to quickly bring products and services to the market.

Despite your industry, an IoT strategy can be shaped to help fuel your existing initiatives.

2. Everyone Over Designs

Moving from IoT strategy to value is complex.

There are lots of distractions and rabbit holes to go down.

Achieving your IoT initiatives requires focus.

By this, I am referring to the importance of strategically mapping out the innovation that you are looking to drive.

Before deploying an IoT strategy, make sure to ask yourself if the concepts you are looking to implement match to the strategies you are pursuing.

3. There Is No Time Like The Present

Don’t over think it, just get started.

Your company has a chance to take part in one of the greatest economic value adding opportunities of a lifetime.

This is your chance to embrace change and see all it has to offer.

Companies that are able to identify the opportunities and quickly bring to market solutions with IoT will be the leaders of decades to come.

4. Think Wrap/Extend, Not Rip/Replace When it Comes to the Internet of Things

The idea behind integrating the IoT into your business strategy should evolve around bettering your processes, not replacing what you have done so far.

This is your time to pro-actively use the IoT to drive growth and optimize your current business operations.

5. The IoT Stack is a Huge Help

The IoT stack is a handy way to break down any IoT project into manageable chunks. Think about it this way.

Before adopting innovative technologies your company must establish frameworks, protocols, and standards that are consistent with your business strategy.

Your framework should revolve around the problems your business is looking to solve.

By breaking down your IoT solution into 5 layers you can better understand the business technology tradeoffs that are needed at each level and the system as a whole.

6. Zealots and Laggards Are Everywhere. Beware.

It’s easy to get distracted by the daily grind and to put off getting started.

Change is a scary thing for all of us, so it’s easy to procrastinate.

Doing nothing is one of the biggest threats when it comes to the Internet of Things.

The reality is, big change is what can define success.

Don’t let your company develop a reputation as a technical laggard in the IoT arena.

7. Avoid The Simple Small Tool Sets

If you’ve ever heard the saying “go big or go home”, it defiantly applies to an IoT strategy.

So often I see companies who are hesitant to make a big change, resorting to small easy to adapt ideas.

If your company wants to see real results, you must avoid wasting your time on the small and simple projects.

Running test pilots to assess potential value is not how you will reach your real strategic initiatives.

To see change, you must make a change. This is when you need to roll up your sleeves and make a connection to your real business issues.

8. The Control Engineers Are The Key to Success

On IoT projects, get to the Controls engineer — this is who has the keys to unlock the room or path to data that might already exist.

Who is your control engineer? This is the person that brings together disparate systems within your network.

A good control engineer knows how to design, develop, and implement the systems that will control your specified applications, networks and machines.

9. IoT is a Big Concept and Many Have Different Views

After introducing the concept of the Internet of Things to many different companies; it has become apparent there are many diverse views of IOT along with its purpose and benefit.

It’s important to remember that two people who seem to differ on the topic of IoT may simply be looking at opposite sides of the same spectrum.

IoT solutions offer limitless capabilities that can easily be tailored to your specific business needs.

This means what IoT can offer for your business, may be completely different than the purpose and benefit it can offer for another.

10. There Is Always a Way To Do Something with IOT

The Internet of Things can be applied to just about every business strategy that exists; it’s just a matter of working at it.

For example, IoT has been used for the complex systems of products like John Deer’s Farmsight to optimize the farm, to simple examples like the Babilat tennis racket that provides data about a player’s performance.

Device connectivity and data analytics enable a closed-loop, real-time digital thread that can connect your people, systems, and equipment across the entire supply chain.

With the rapid creation and developments of new IoT applications, any organization can connect, manage, and optimize complex sets of disparate systems.

See how IoT goes beyond connecting products and has expanded to enable manufacturing and service processes by reading these case studies from PTC.

When it comes to IoT, there is always a way to do something.