If you don’t already know me, I am an Additive Manufacturing Specialist (a fancy name for a 3D printing expert) at EAC Product Development Solutions.

I specialize in Formlabs 3D desktop printers and often give tips and tricks to help you make the most out of your 3D printer investment. Follow me on my LinkedIn for more tips and tricks!

I receive quite a few emails on part orientation and would like to share with you a tip using PreForm, Formlabs’ free 3D printing software.

Download PreForm Software

Download PreForm for Mac.

See Requirements for OS X 10.10 or higher

Download PreForm for Windows.

See Requirements for Windows 7 (64-bit) or higher

Part Orientation using PreForm Software

In this tip, I’ll show you how you can be more successful with your prints using Formlabs printer software. The software is very intuitive and I love sharing what I’ve learned to make things easier for those using the Form 2 or Form 3 SLA printers!

Watch my video or read the transcript below!

Transcript from Tip Video

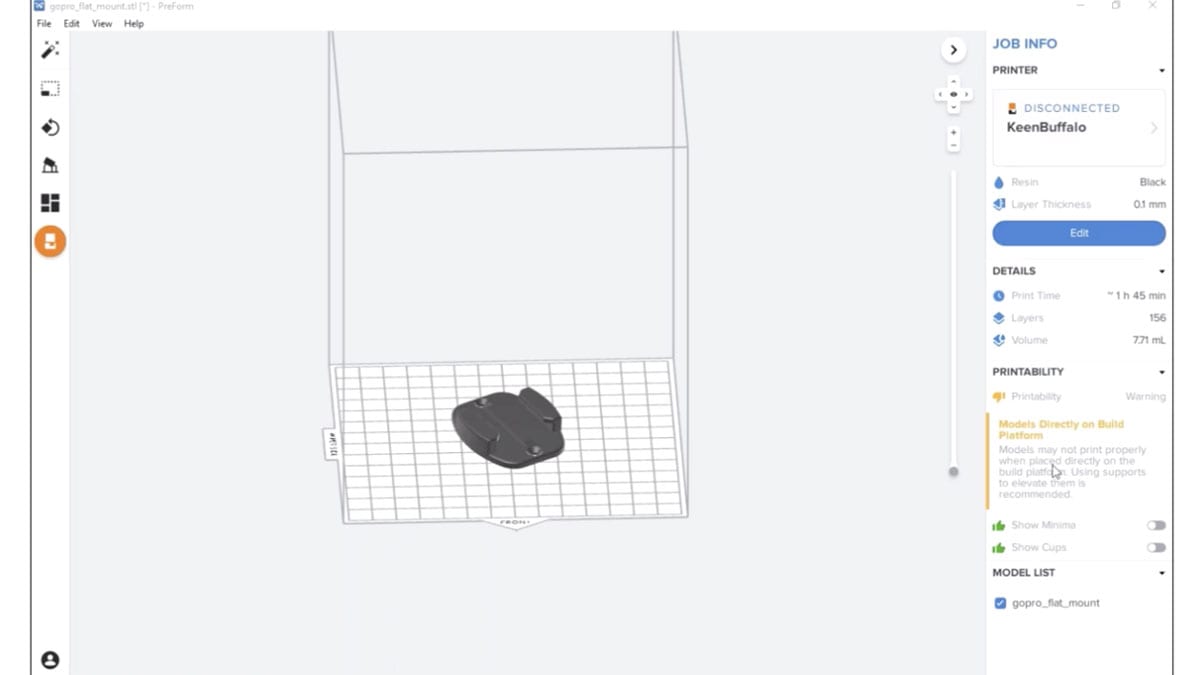

I have PreForm open here and I have Go Pro mount clip imported for us to use as our model today. I just want to show you guys a couple of quick things here.

Step 1: Open file of model

Off to the left side, we have our Quick Access menu buttons and off to the right side, we have our status bar showing us the print time, how many layers are printing, the volume, printability of the model, etc.

Step 2: Get familiar with the software

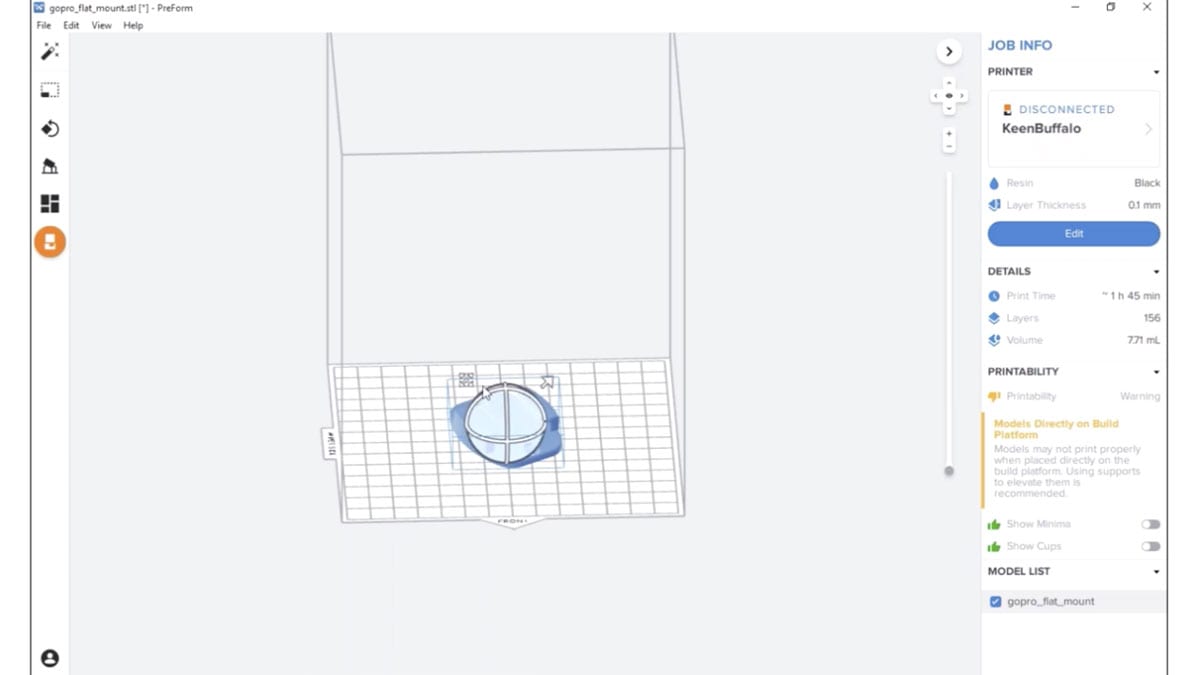

What we want to do when we get started is to make sure our model is set up how we want it to be. I want to make sure it’s oriented properly. So what I can do is click on it to select it, once it’s blue, it shows that it’s selected. I’m going to drag it to tilt the model.

Step 3: Click on model to select (should appear blue)

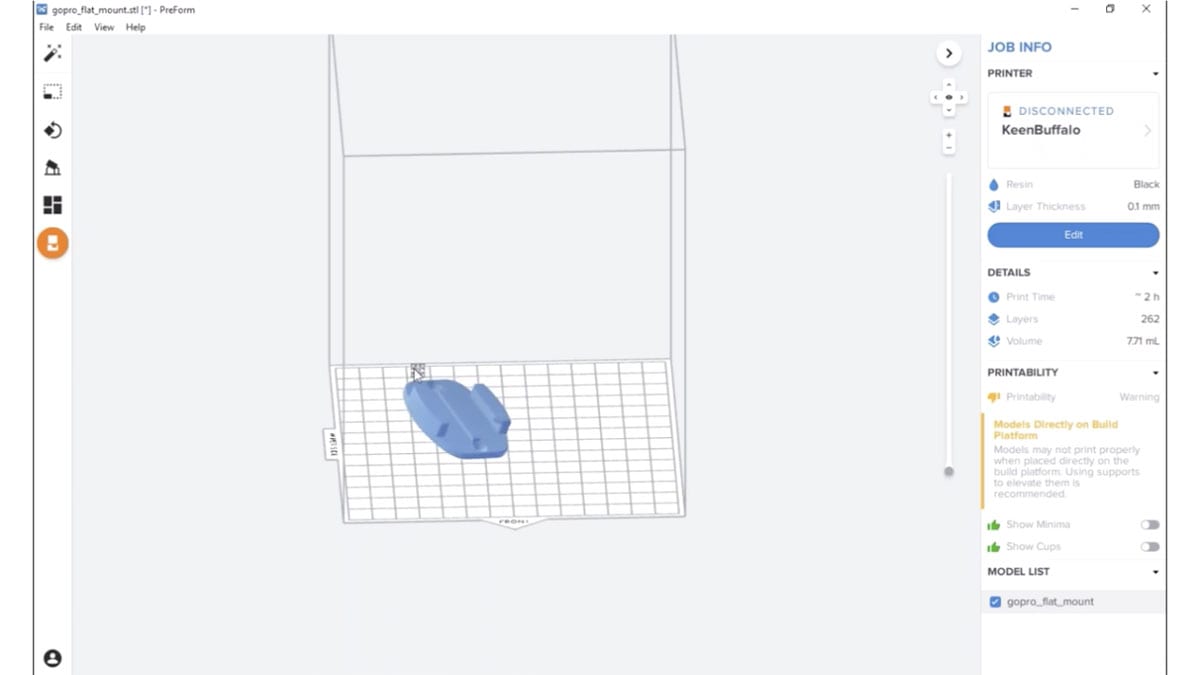

You can even use the directional key to move it over to each side if you want to place more of the parts on the build platform.

With parts that have these larger, flat surface areas – you’ll want to tilt them at an angle of at least 10-20 degrees to improve your success rate for printing. Printing at an angle reduces the surface area of each layer which in turn creates less force on the part.

Step 4: Tilt model at an angle

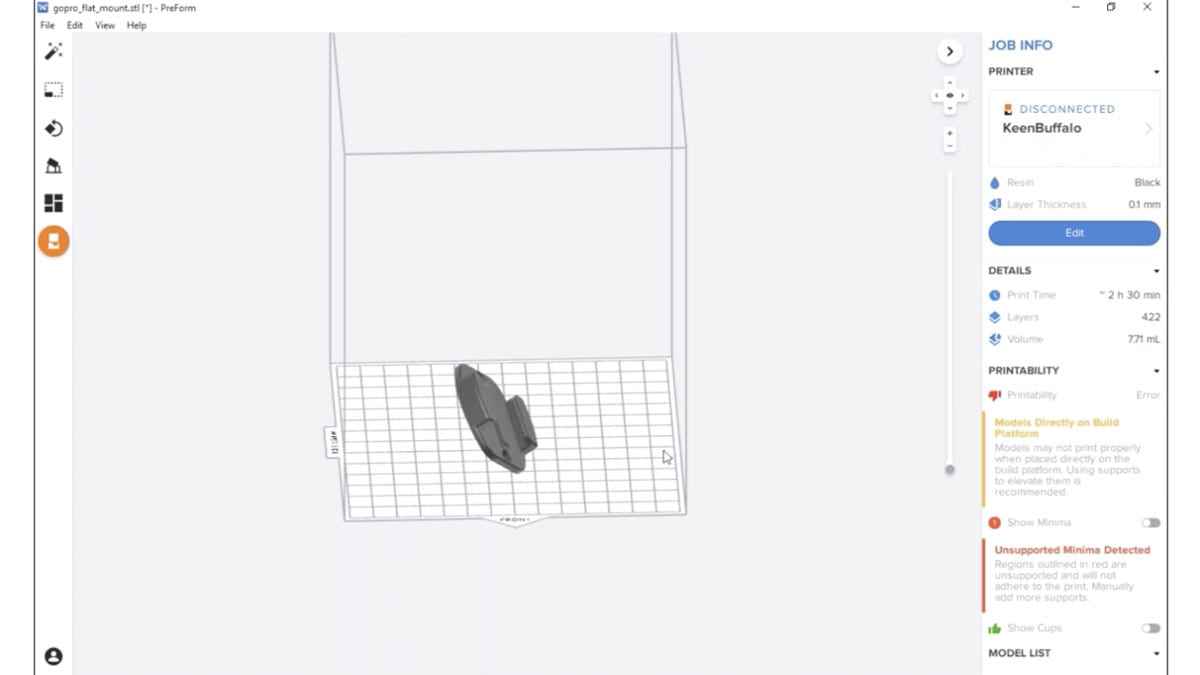

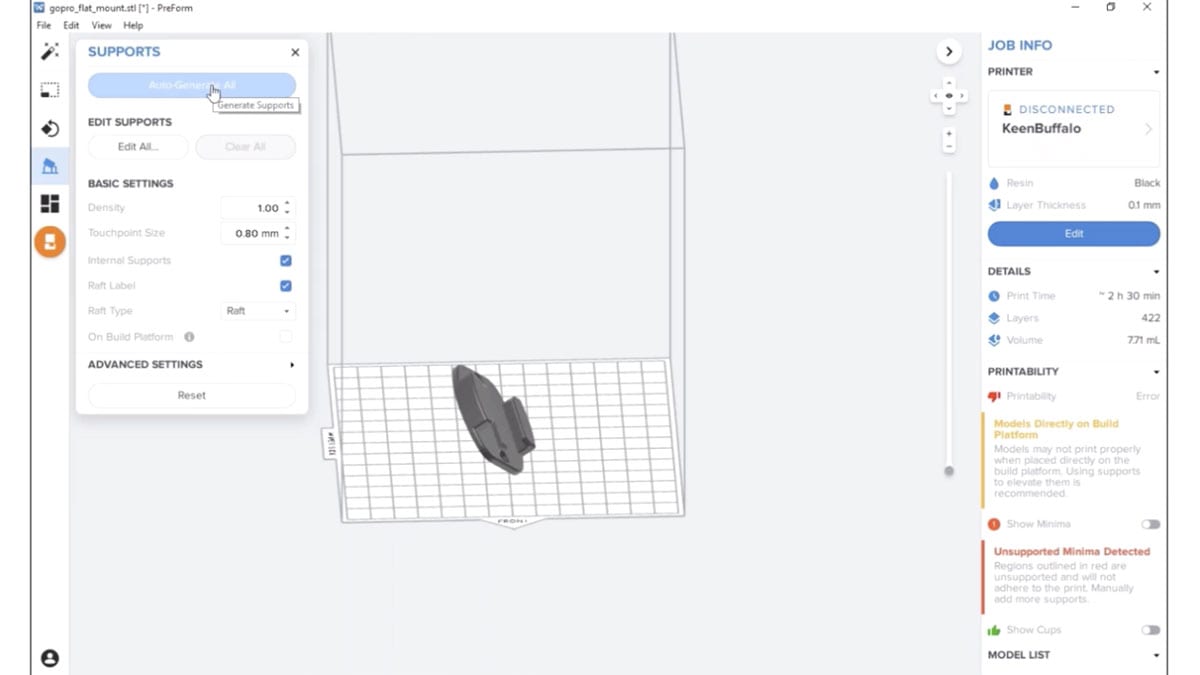

Now that we have it oriented properly, we’ll want to create the supports. I’m going to go to the left side to the support button on the Quick Access menu – to generate all of them automatically. You can manually add them if you’d like. It only takes a minute to generate the supports for you.

Step 5: Generate the supports for your model

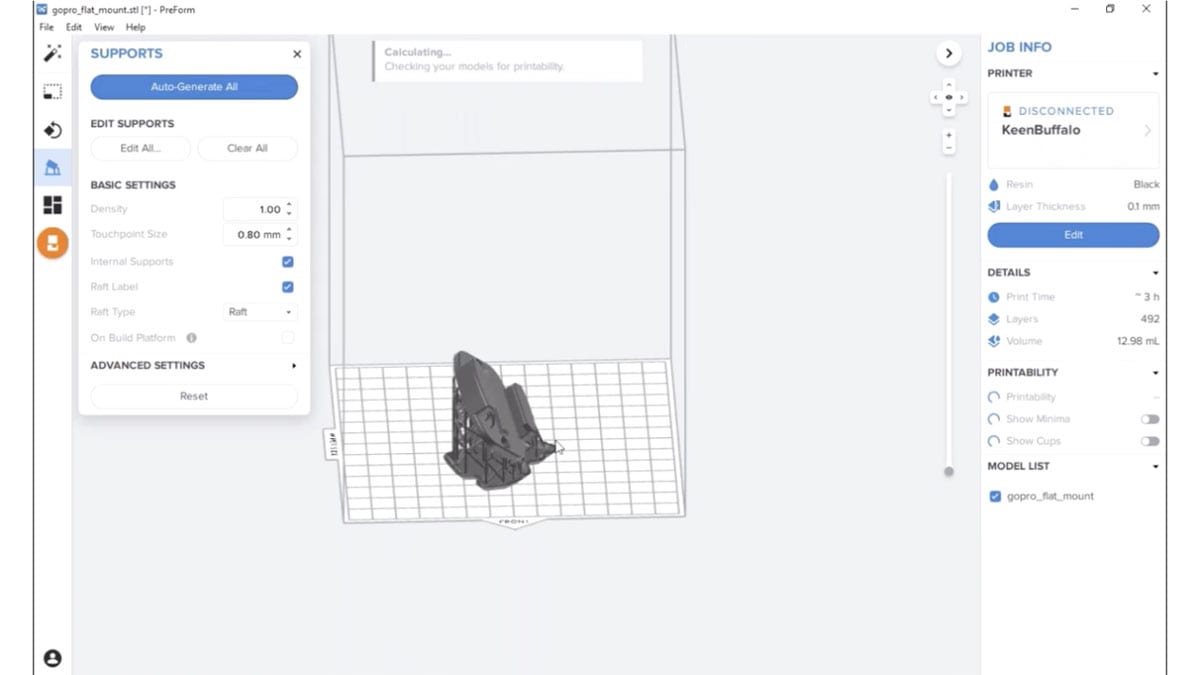

Once the supports are generated, you’ll want to take a look at the model and make sure it’s set up the way you want it to be.

Step 6: Approve/Modify generated supports

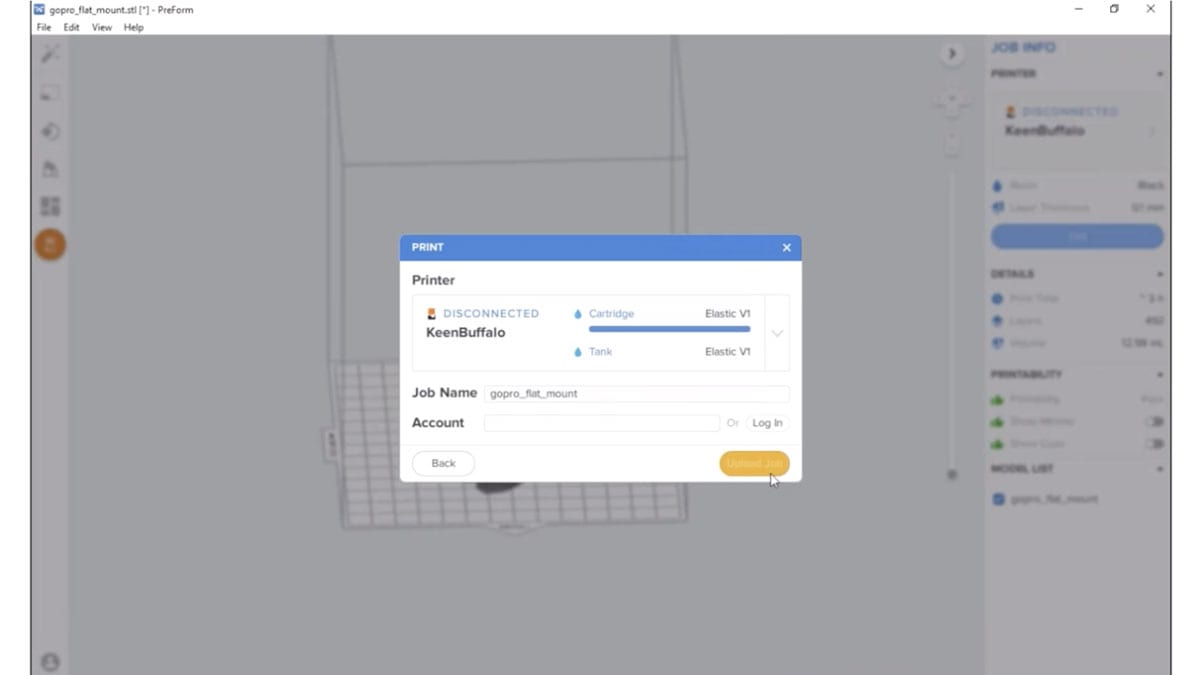

Once you’re satisfied with the model, you’ll just click on your printer button on the left side where the Quick Access menu is, choose the desired printer, and then you upload the job to your 3D printer.

Step 7: Send model to printer

Interested in learning more about 3D printing on the shop floor?! Watch our free educational video on finding more opportunities for additive manufacturing.